Blog Information

- Posted By : ao xu

- Posted On : Dec 08, 2022

- Views : 74

- Category : Technology

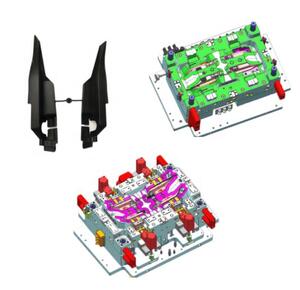

- Description : How does Custom Automotive Injection Mold's Plastic Injection Mold work?

Overview

How does Custom Automotive Injection Mold's Plastic Injection Mold work?

Simply put, injection molding is a manufacturing process used to make parts and products as quickly and efficiently as possible without sacrificing quality. A molding machine injects liquid plastic or metal into a mold to make a product. Manufacturers can use this technique to create multiple parts simultaneously in rapid succession.

What is injection molding

Injection molding is most often used when a manufacturer needs to manufacture large quantities of plastic products (often over 100 pieces). This method offers many advantages, most importantly low unit cost. Injection molding creates a surprising number of everyday objects. In fact, there's a good chance you're nearby right now. From computer mice to car parts, injection molding is an integral part of our lives.

Injection molding process steps

melt plastic

Inject molten plastic into the mold

Let molten plastic cool to a solid state

Removal of hardened product from mold

Alternative Text - Metal Injection Template

Injection molding process control

When it comes to the quality of molded products, there are many specific processes that must be considered and controlled.

As the key to the entire injection molding process, temperature has a huge impact on the performance of the mold. Every plastic material has a specific melting point, so different projects require careful adjustment.

Another factor that needs to be monitored and controlled is pressure, which applies to injection molding and mold cavities. Too much pressure can cause material to squeeze out of the die. Too little will result in an incomplete product.

Plastic injection molding process problems

Some questions are unavoidable, but the information you get here will help you understand what to look out for. With this in mind, you'll be better able to communicate quality issues with your molders and optimize your relationship.

Short Shots - The mold is not fully filled and the part is incomplete

Twill - Visible gray or silver streaks on the finished product due to excess moisture in the material

Weld line - a line or seam formed where liquid material gathers

Burns - product burn marks from air trapped in the mold

Flashing - Plastic overflows from the cavity to form a thin layer of plastic that sticks from the part that must be trimmed

Sink – A dimple or depression in the part, caused by low pressure in the die