Blog Information

- Posted By : pipingmaterial pipingmaterial

- Posted On : Mar 23, 2023

- Views : 217

- Category : General

- Description : Hastelloy is a nickel alloy that is extremely strong and corrosion-resistant, making it ideal for harsh chemicals and acids. The high temperature and corrosion resistance qualities are enhanced by including chromium and molybdenum. The malleability of Hastelloy plate suppliers allows it to take on a wide variety of shapes.

Overview

A steel plate is a flat sheet of steel that can be further processed into various manufactured goods. Steel plates can be cut to any size you require in terms of length or width and are available in multiple thicknesses. The following are a few examples of steel plates:

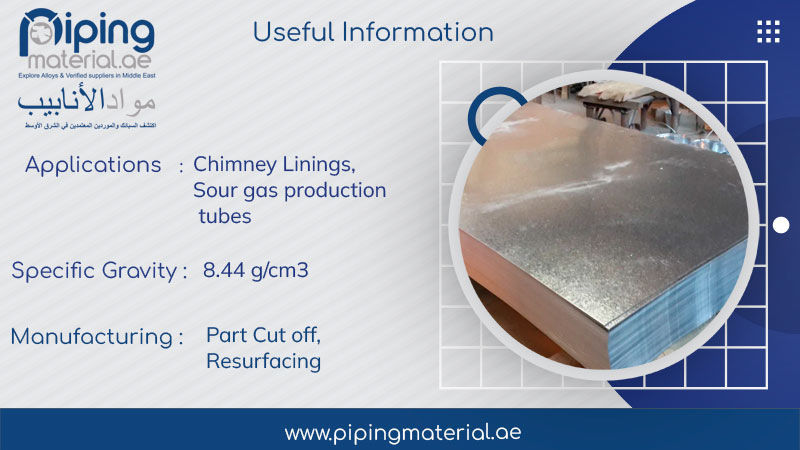

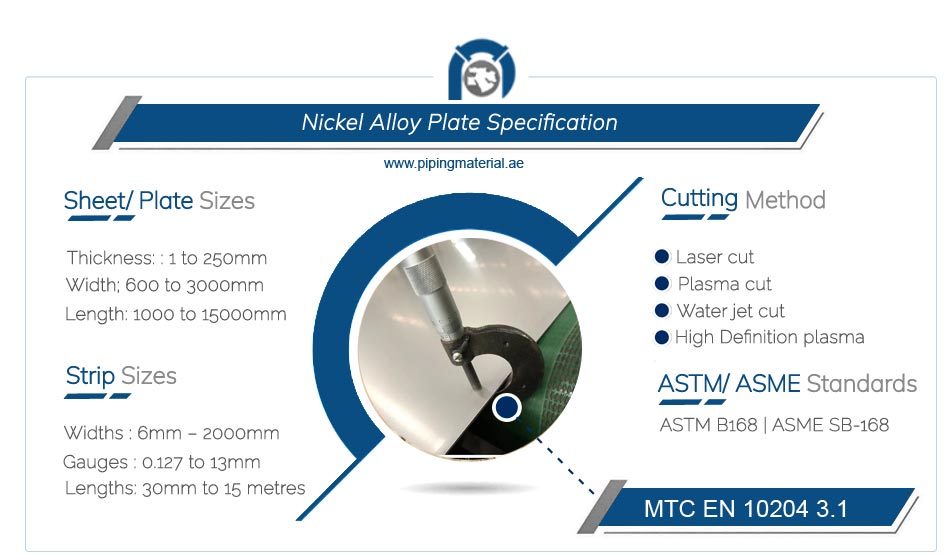

- A plate of nickel alloy

Metal parts made from nickel alloys are known for their durability and resilience. The increased strength of the Nickel alloy plate suppliers comes from the combination of nickel and other elements. Nickel Alloy Sheet is resistant to corrosion and oxidation in many stress environments.

- Inconel plate

Inconel plate suppliers and sheets are high-temperature alloys containing nickel, chromium, molybdenum, and other metals. These alloys find use in many applications, including gas turbines, nuclear reactors, and equipment used in the chemical processing industry.

- Sheets of Monel metal

Nickel, copper, iron, manganese, silicon, carbon, and sulphur go into making a Monel Alloy 400 Plate. Monel plate suppliers offer high strength and resistance to corrosion because of the high-quality materials used to make them. There is no oxidation in the chloride solutions used on these plates. Therefore, they are resistant to stress-corrosion cracking.

- Hastelloy plate

Hastelloy is a nickel alloy that is extremely strong and corrosion-resistant, making it ideal for harsh chemicals and acids. The high temperature and corrosion resistance qualities are enhanced by including chromium and molybdenum. The malleability of Hastelloy plate suppliers allows it to take on a wide variety of shapes.

- Duplex plate

The austenitic and ferritic microstructures work together to create the formidable dual-microstructure grade known as a duplex. The elements that make up the Duplex plate suppliers’chemical makeup are carbon, manganese, silicon, phosphorus, sulphur, chromium, molybdenum, nickel, nitrogen, and copper. Duplex stainless-steel plate is very corrosion-resistant and can withstand extreme conditions.

- Super duplex plate

Nitrogen-alloyed 22% Chromium, 3% Molybdenum, and 5-6% Nickel create Super duplex plate suppliers, a duplex stainless-steel plate with high strength and great impact toughness. It also demonstrates excellent general, localised, and stress corrosion resistance.

- High-strength steel sheet

Plates and sheets can be fabricated from and strengthened with High strength steel plate. To what extent these plates inherit their additives' qualities is entirely up to those substances. Strength, formability, and weldability are all enhanced in High strength steel plate.

- Structural steel plate

Building materials often include metals like structural steel. In its most basic form, it is defined as steel modified for use in building construction. This distinguishes it from a grade of steel that might be used to engineer tools, as well as stainless steel, which is commonly used in the surfaces and appliances of kitchens.

Carbon steel, which is what is typically meant by Structural steel plate suppliers is a steel whose chemical makeup includes both iron and carbon. Every type of steel up to 2.1% carbon by weight is considered structural steel. Higher carbon content increases the yield strength of steel, making it less malleable and more resistant to deformation under stress.

Conclusion

Bridges and other heavy structures often use steel plates to fortify their bases and maintain weight. On the other hand, it can be used as a foundation for building bulkier materials or non-functional components. Steel Plate uses depend heavily on the nature of the undertaking.