Blog Information

- Posted By : Angela Goble

- Posted On : Nov 18, 2023

- Views : 102

- Category : General

- Description : Hoping that you will understand the difference between CNC and conventional machines. Both of them are used for manufacturing products. CNC machines are more precise than conventional ones because they are controlled through computer programs. You can choose any one according to your business requirements - CNC machines produce large volumes whereas conventional produce small tasks. Are you looking for cost-effective precision in manufacturing? You can explore a wide range of used gear cutting machines for sale.

Overview

What is Conventional Machining?

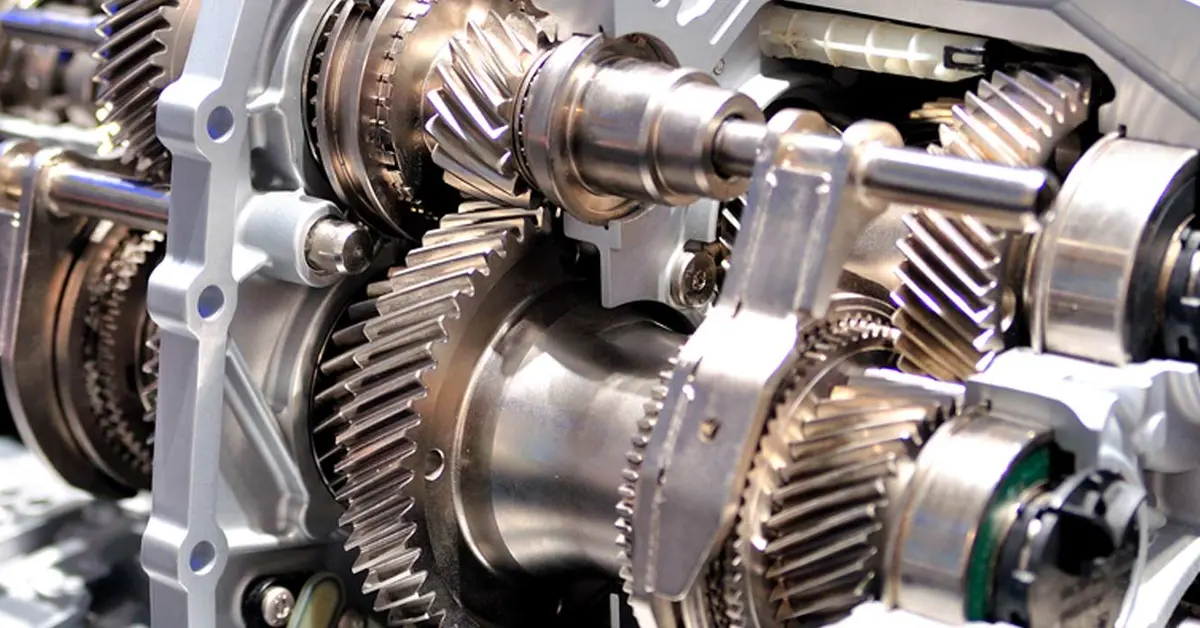

Despite being advanced technologies, conventional machines are operated by human beings to control the machine process and tools. It comprises boring, drilling, milling, and other various sharp cutting-edge solutions. To obtain the end results of product geometry, the individual is solely responsible for controlling the location, machine, and force of tool contact with the raw material via buttons, levers, or wheels. Moreover, hand milling machine can be accessed by skilled operators, creating prototypes and aiding CNC machines in production processes.

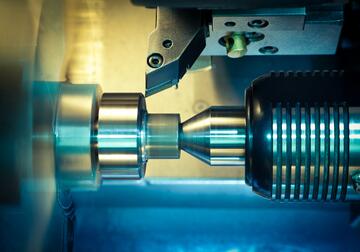

What is CNC machining?

CNC machining also operates by individuals but with more advanced software or techniques. All operating functions are controlled by computer programs that instruct the movements of the machining tools. The CNC technique does not require the tools to put into touch with the raw materials.

Automation and Control

CNC machines rely on computer-controlled and automated metal manufacturing processes. These automated machines follow the proper commands or instructions given by people. Moreover, this will reduce the extra cost of operator intervention. Transform your CNC machines for more precision and longevity with used sharpening machines for sale.

On the other hand, conventional machines are operated by individuals who rely on the operator's skill and experience to adjust movements and adjustments. You can notice slighter differences in the quality of desired products.

Cost

CNC machines are more expensive because computer commands operate them.

On the flip side, conventional machines are affordable and less expensive. So you can consider for used metalworking machinery if your budget is limited.

Precision

CNC machines are incredibly precise. They can produce precise and highly intricate work with no or minimal errors and are also experts in creating complex products. Therefore, they are perfect for jobs requiring a high degree of accuracy. If you want a more intricate machining task, used 5 axis milling machine for manufacturing products.

Conventional machines can also render precise results, but the involvement of a human touch renders a slight variation in the results of the product's quality.

Versatility

The versatility of CNC machines can perform different tasks such as grinding, cutting, drilling, milling, and many more. It is suitable for a variety of materials and is used in various applications, which include health, automotive, and aerospace.

Conventional machines can perform only specific tasks. They need to be retooled entirely and adjusted to be modified for new applications.

Production Volume

CNC machines are suitable for small tasks and large-scale production because of their precision and automation features. You can buy a CNC machine if you have a large manufacturing area and want products in large numbers.

On the other hand, conventional machines suit small-volume, custom, or prototyping tasks.

Skills and Experience

Operators with less experience or skills can produce high-quality and consistent products because CNC machines are commanded through computer programs.

Only highly experienced and qualified operators can access Conventional machines with a slight variation in end products. It also influences quality and consistency.

Setup Time

CNC machines can be set up quickly and in less time because of the availability of automated tool changes and adjustments, thus reducing downtime.

Conventional machines require longer setup times because of manual adjustments and tool changes.

Summing It Up

Hoping that you will understand the difference between CNC and conventional machines. Both of them are used for manufacturing products. CNC machines are more precise than conventional ones because they are controlled through computer programs. You can choose any one according to your business requirements - CNC machines produce large volumes whereas conventional produce small tasks. Are you looking for cost-effective precision in manufacturing? You can explore a wide range of used gear cutting machines for sale.