Blog Information

- Posted By : keneng keneng

- Posted On : Mar 25, 2024

- Views : 168

- Category : General

- Description : This guide provides an in-depth walkthrough of utilizing a muffle furnace effectively, covering everything from setup procedures to temperature control and sample handling.

Overview

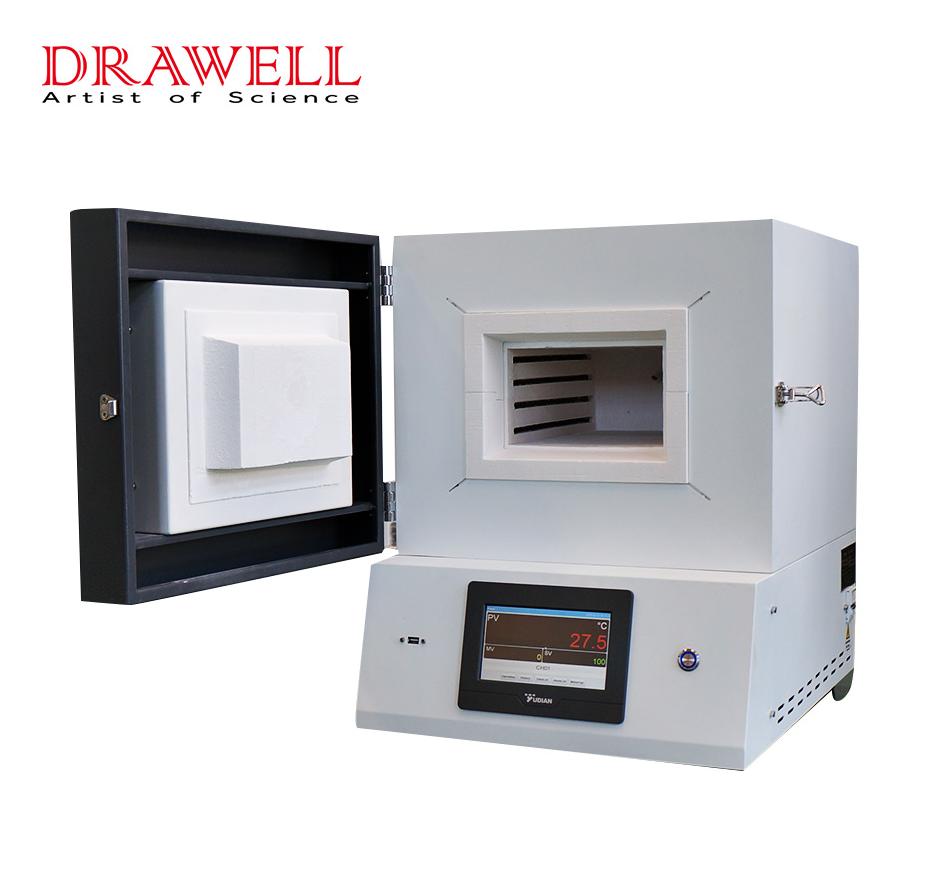

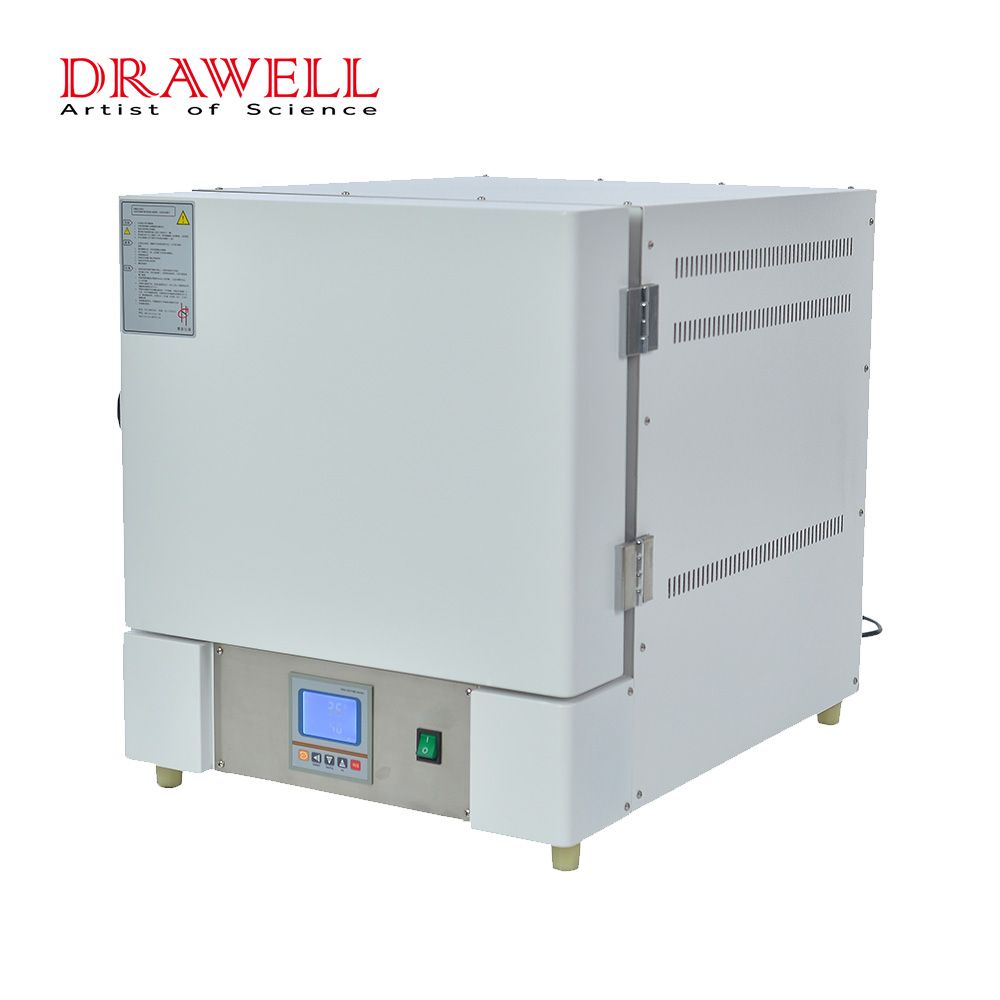

In laboratories and industrial environments, the muffle furnace stands as a stalwart tool for high-temperature applications. Whether it's heat-treating materials, conducting material testing, or executing ashing experiments, understanding the correct operation of a muffle furnace is paramount. This guide provides an in-depth walkthrough of utilizing a muffle furnace effectively, covering everything from setup procedures to temperature control and sample handling. By adhering to these steps, you can optimize the efficiency and safety of your experiments while ensuring precise and consistent results.

1. Safety Precautions:

Prioritize safety by donning appropriate personal protective equipment (PPE) such as heat-resistant gloves, goggles, and a lab coat.

Ensure the workspace is devoid of flammable materials and adequately ventilated.

Familiarize yourself with emergency shutdown procedures and the location of fire safety equipment.

2. Furnace Preparation:

Verify the power supply's integrity and ensure proper grounding.

Clean the muffle chamber meticulously, removing any debris or remnants of previous samples.

Confirm the secure insertion and closure of the muffle, the heating chamber, within the furnace.

3. Temperature Settings:

Refer to the operating manual specific to your muffle furnace model to comprehend its temperature control system intricacies.

Utilize temperature control knobs or digital displays to establish the desired temperature for your experiment.

Take note of any prescribed heating rates or ramping instructions pertinent to your application.

4. Sample Loading:

Prepare your sample meticulously in accordance with the experiment's specific requirements.

Employ suitable crucibles or containers capable of withstanding high temperatures.

Ensure precise positioning of the sample within the muffle chamber to facilitate accurate heating.

5. Furnace Closure:

Securely seal the muffle furnace upon loading the sample to prevent any heat loss.

Verify tight sealing of the furnace door to maintain optimal operational conditions.

6. Initiation of Heating Process:

Activate the muffle furnace by following the manufacturer's stipulated instructions upon turning on the power supply.

Witness the commencement of heat generation by the heating elements, initiating the furnace's ascent towards the set temperature.

7. Process Monitoring:

Keep vigilant watch over the temperature display or indicator throughout the heating phase.

Regularly assess the temperature within the muffle chamber to ensure its alignment with the desired parameters.

Exercise restraint in opening the furnace door unnecessarily to forestall heat dissipation and temperature fluctuations.

8. Cooling Down Phase:

Upon completion of the heating cycle, gradually decrease the furnace's temperature in accordance with your experimental prerequisites.

Permit the furnace to cool to a safe level before contemplating opening the door.

9. Sample Retrieval:

With due caution, carefully open the furnace door once the cooling process has sufficiently progressed.

Employ appropriate tools such as tongs or heat-resistant gloves to extract the sample from the muffle chamber, mindful of its potentially elevated temperature.

10. Cleaning and Maintenance:

Following the experiment's conclusion, undertake thorough cleaning of the muffle furnace to eliminate any residue or debris left behind by the sample.

Adhere strictly to the manufacturer's guidelines delineating specific cleaning and maintenance procedures, thus ensuring the durable muffle furnace with long service life.

Conclusion:

In summary, proficiency in utilizing a muffle furnace is indispensable for conducting a myriad of high-temperature applications. By adhering meticulously to the steps outlined in this guide, you can ensure both the safe and efficient operation of your muffle furnace while upholding the integrity of your samples. Always prioritize safety precautions and consult the manufacturer's instructions pertinent to your furnace model. With consistent practice and adherence to proper techniques, you can wield the potency of a muffle furnace with confidence, accomplishing precise heat treatments, material tests, and other thermal processes adeptly.