معلومات المجموعة

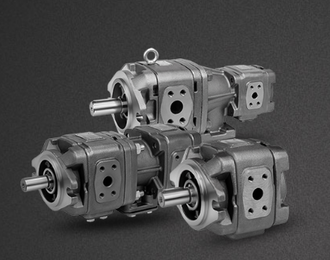

- Design Characteristics Of Internal Gear Pumps علم

- The gear pump is compact and simple, with a limited number of moving parts. The gear pump cannot match the pressure generated by the reciprocating pump or the flow rate of the centrifugal pump, but it has higher pressure and throughput than the vane pump...أكثر من

-

- Cassidy vanepump (صاحب)

-

- ٢٨٢ total views

- مجموع أعضاء ١

- آخر تحديث