Informations sur le groupe

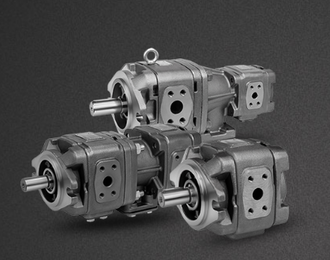

- Internal Gear Pumps: Good Suction Capacity Science

- The gear pump is compact and simple, with a limited number of moving parts. Gear pumps cannot match the pressure generated by reciprocating pumps or the flow rate of centrifugal pumps, but they have higher pressure and throughput than vane pumps or lobe...plus

-

- Cassidy vanepump (propriétaire)

-

- 359 total des vues

- 1 membre total

- Dernière mise à jour