Quanzhou Howfun IMP & EXP Trading Co., Ltd. » Remarques » What are the limitations of FEP tubes?

-

What are the limitations of FEP tubes?

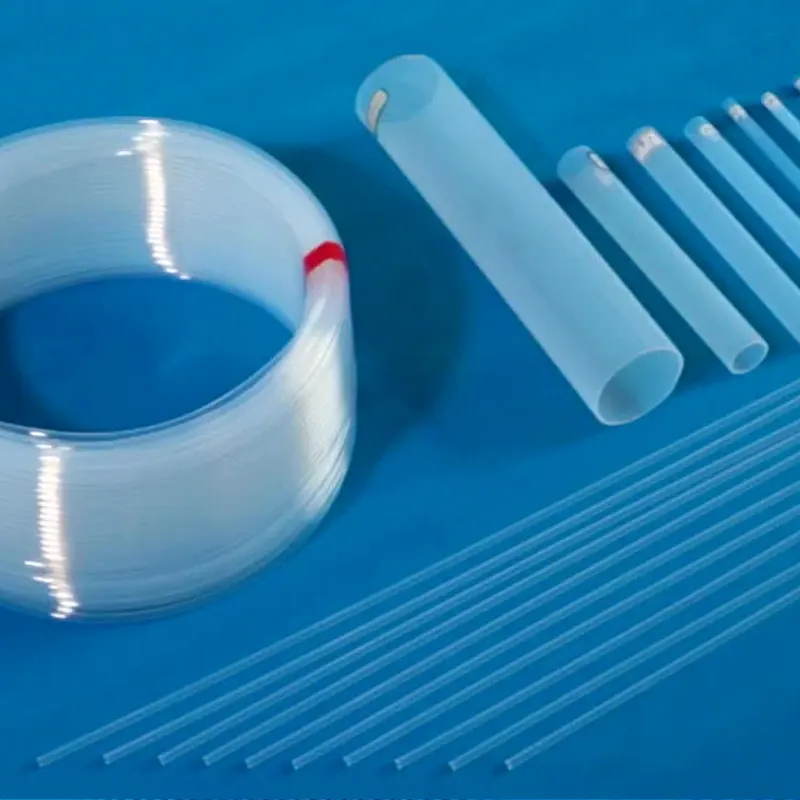

Publié par sino seo - Catégorie: La technologie - 3 vues - 0 commentaire - 0 comme - #China FEP tube manufacturerChina FEP tube manufacturer are widely used in various applications due to their excellent chemical resistance and thermal stability.

However, they do have some limitations:-

Temperature Range: While FEP can withstand high temperatures (up to about 200°C), it may not perform well in extreme heat environments compared to other materials like PTFE.

-

Mechanical Strength: FEP has lower mechanical strength compared to some other thermoplastics. It can be prone to deformation under stress or high pressure.

-

Flexibility: Although China PFA tube manufacturer is more flexible than some other fluoropolymers, it can still be stiffer than desired for certain applications, which may limit its use in tight bends or flexible assemblies.

-

Cost: FEP is generally more expensive than standard plastics, which can be a consideration for large-scale applications or projects with tight budgets.

-

UV Sensitivity: FEP can degrade when exposed to UV light over prolonged periods, which may limit its use in outdoor applications unless properly shielded.

-

Brittleness: At low temperatures, FEP can become brittle, which may lead to cracking or failure in cold environments.

-

Limited Adhesion: Due to its non-stick surface, FEP can be difficult to bond with other materials, which may pose challenges in assembly or repair processes.

-

Chemical Compatibility: While FEP is resistant to many chemicals, it may not be compatible with certain aggressive solvents or chemicals, requiring careful selection based on specific applications.

Understanding these limitations is crucial when selecting materials for specific applications to ensure optimal performance and durability.

-