What is CNC Turning?

Posté par Gillian Chen

Corps

What is CNC Turning?

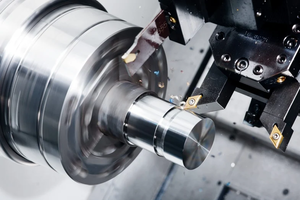

CNC Turning is a commonly form of CNC Machining. It involves a subtractive process where the workpiece is rotated at high speeds while a cutting tool methodically removes material. Discover the essentials of CNC Turning with our comprehensive guide.

Definition of CNC

CNC stands for Computer Numerical Control, a term encompassing a computer-driven manufacturing process.

Designs are initially created using CAD (Computer-Aided Design). This CAD file is then transformed into a computer program that controls the CNC turning machine, guiding the cutting tools with precision through lines of code, often in the G-code format.

The Turning Process

Turning involves securing raw material bars, which are then rotated at high velocities. As the material spins, a cutting tool is applied to carve out the desired shape.

Unlike other methods where the cutting tools move, in turning, the workpiece itself rotates. Typically used for cylindrical workpieces, CNC Turning can also handle square or hexagonal materials, held in place by a 'chuck' that spins at various RPMs (rotations per minute).

Modern CNC Turning machines are computer-monitored, ensuring precise and consistent results. Equipped with various tools and spindles, these machines can handle a wide array of geometries, especially tubular and circular shapes.

CNC Milling vs. CNC Turning

The shape of the part and the production volume are primary factors in deciding between CNC milling and turning.

- Type of Workpieces: CNC Milling is suitable for complex 3D parts, while CNC Turning is more specialized in cylindrical symmetrical parts.

- Complexity of Machining: CNC Milling can handle more complex geometries, whereas CNC Turning is more professional in machining parts with symmetrical requirements.

- Production Efficiency: CNC Turning is usually more efficient in mass production, while CNC Milling offers more flexibility in low-volume or one-off production.

Advantages of CNC Turning

CNC Turning excels in producing symmetrical or cylindrical parts swiftly and in high volumes. This process ensures high-quality parts with extremely smooth finishes. CNC Turning capabilities include:

- Drilling

- Boring

- Reaming

- Taper Turning

Applications of CNC Machines

CNC machines are adept at creating highly accurate and high-quality parts through subtractive machining technology. Materials that benefit from CNC Machining include:

- Aluminium

- Steel

- ABS

- Titanium

- Copper

- PP

- PEEK

- Brass

- Nylon

commentaires