-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Ceramic PCB #metal core pcb manufacturer #Ceramic Substrate PCB

-

- Last updated June 18, 2024 0 comments, 128 views, 0 likes

- United States - Get Directions

More from Hitech Circuits Co Limited

More in Politics

Related Blogs

Innovations in LED PCB Assembly: Staying Ahead in Technology

Body

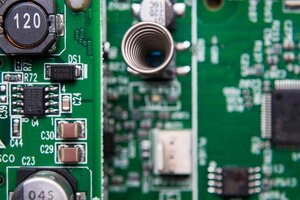

In the world of electronics manufacturing, LED PCB assembly plays a crucial role in ensuring the performance and reliability of LED products. Let's explore what LED PCB assembly entails and its significance in the industry.

What is LED PCB Assembly?

LED PCB assembly refers to the process of assembling printed circuit boards (PCBs) that are specifically designed to accommodate LEDs (Light Emitting Diodes). These boards are engineered to provide electrical and mechanical support to the LEDs, ensuring proper functioning.

Components Involved in LED PCB Assembly

The assembly typically involves components such as LEDs (SMD or Through-Hole), resistors, capacitors, and connectors. These components are carefully soldered onto the PCB using advanced manufacturing techniques.

Importance of Quality in LED PCB Assembly

Quality is paramount in LED PCB assembly to guarantee longevity and performance consistency of LED products. Factors such as proper thermal management and precise soldering contribute to the overall quality of the assembly.

Technological Advancements in LED PCB Assembly

Advancements in manufacturing technology have led to innovations like Surface Mount Technology (SMT) and automated assembly processes. These advancements enhance efficiency and accuracy in LED PCB manufacturing.

Applications of LED PCB Assembly

LED PCBs find applications across various industries including automotive lighting, consumer electronics, and industrial lighting. Their versatility and energy efficiency make them indispensable in modern-day technology.

Choosing the Right Partner for LED PCB Assembly

Selecting a reliable manufacturer like Hitech Circuits Co. Limited ensures high-quality LED PCB assemblies. Their expertise in PCB manufacturing and commitment to technological advancement make them a preferred choice.

Why Hitech Circuits Co. Limited Stands Out

- Advanced Facilities: State-of-the-art manufacturing facilities equipped with the latest technology.

- Quality Assurance: Rigorous testing processes to maintain superior quality standards.

- Customization Options: Ability to tailor LED PCB solutions according to client specifications.

Future Trends in LED PCB Assembly

The future of LED PCB assembly is poised for further advancements in miniaturization, efficiency, and environmental sustainability. Innovations such as flexible PCBs and smart lighting systems are on the horizon.

Photos

Map

-

Locations on MyWorldGo

Location Information

- Location: United States - Get Directions

- Formatted Address: United States

- Country: United States

Comments