-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

-

- Last updated September 14, 2018 0 comments, 439 views, 0 likes

More from gong liang

More in Politics

Related Blogs

Archives

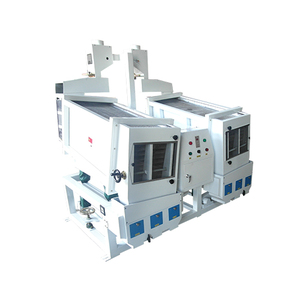

Paddy Separator Dismantling Tips

Body

Paddy Separator(LIANGGONG) Tips:Paddy separator needs installation debugging when it is just put into production. During this period, it may need disassembling. So we should be very careful. If we don’t pay attention to these details in paddy separator dismantling, it may be harmful to the paddy separator.

The following are the points which we should pay attention to in paddy separator dismantling:

1. We need the most suitable tools for paddy separator dismantling. Don’t hit or knock heavily to prevent the parts to be broken or be out of shape.

2. Clear the surface soil or greasy dirt before disassembling. Keep clean during paddy separator dismantling.

3. After disassembling, classify and store the parts according to material nature and parts precision measure.

4. Disassemble the paddy separator according to needs. Try to disassemble the paddy separator as less as possible, and don’t disassemble the equipment if there has no needs.

5. Prepare enough for assembling of the paddy separator when disassembling it. Notice to check the signs when we disassemble the equipment so as to improve its efficiency and accuracy.

6. Disassemble the paddy separator by sequence. Usually we dismantle the machine from accessories to master parts, from outer to inner, from the whole machine to assemble and finally to each part of paddy separator.

Click Paddy Husker to learn about more information.

Comments