-

Retrouver dansMembres

Retrouver dansMembres Retrouver dansVidéos

Retrouver dansVidéos Retrouver dansChaînes

Retrouver dansChaînes

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Cliquez iciPréférence de confidentialité

- Mots clés - #evaporator

-

- Dernière mise à jour 23 mai 2022 0 commentaire , 162 vues, 0 comme

More from shanhe coils

More in Politics

Related Blogs

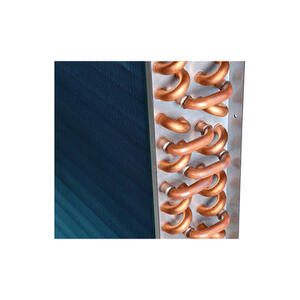

The Function And Principle Of The Evaporator

Corps

The condenser is a part of the refrigeration system and belongs to a type of heat exchanger. It can convert gas or vapor into liquid, and transfer the heat in the tube to the air near the tube in a fast way. There are four main components in the basic refrigeration system of the chiller: compressor, evaporator, condenser, and expansion valve. In addition, in order to improve the performance of the refrigeration system and achieve better performance, there are usually many auxiliary devices: liquid pipeline solenoid valve, sight glass, liquid pipeline drier filter, high and low-pressure controller, etc. Today, I will briefly introduce what an evaporator is.

When the freon liquid in the refrigeration system enters the expansion valve and is throttled and then sent to the evaporator, it belongs to the vaporization process. At this time, a large amount of heat needs to be absorbed, so that the temperature of the cooled price and quality is gradually reduced, so as to achieve the effect of cooling and cooling. Then, according to the type of medium to be cooled, it can be divided into two categories: evaporators for cooling liquid (water) (dry evaporators) and evaporators for cooling air (surface-cooled evaporators).

The main introduction here is the evaporator used in the chiller refrigeration system, which is generally a dry shell and tube evaporator. The refrigerant evaporates in the heat exchange tube, and the water flows on the side of the shell and tube. In order to increase the heat exchange efficiency, a 2mm thick water baffle is set on the side of the shell and tube, so that the water can flow back and forth from side to side to achieve the purpose of producing ice brine. The shell of the container is more than 6mm thick. It is made of steel pipe, which can withstand the pressure of 10 Kg/square centimeter, and the outside is insulated with PE foam board. The heat exchange tube is made of high-efficiency seamless red copper tube, which is processed into an internally threaded ribbed tube by an embossing process, which increases the heat transfer area and improves the heat transfer efficiency, with a pressure resistance of 20 Kg/square centimeter; The heat exchange tube and the end plate are combined with the expansion tube, and the partition plate is added in the end cover to divide the refrigerant into multiple flows to maintain the return of the refrigeration oil. It can tolerate a scaling factor of 0.086 M2°C/KW, and the water pressure drop through the evaporator does not exceed 6.5mAq.

For more details, check out the Industrial Evaporator Coil Factory!

commentaires