-

Encontrar enMiembros

Encontrar enMiembros Encontrar enVideos

Encontrar enVideos Encontrar enCanales

Encontrar enCanales

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy haga clic aquíPreferencia de privacidad

- Etiquetas - #bridge cutting machine stone cutting machine

-

- Última actualización 17 de noviembre de 2022 0 comentarios, 108 vistas, 0 likes

- 13# Zhitai Road - Obtener las direcciones

More from jack su

More in Politics

Related Blogs

Stone cutting machine maintenance guide

Publicado por jack su

17 de noviembre de 2022

Cuerpo

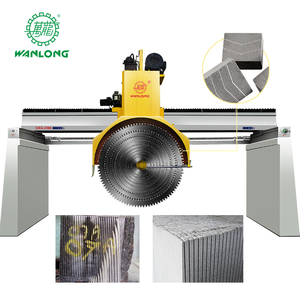

The stone processing industry has a long history. Since the beginning of human activities on the earth, there has been stone processing. Stone machinery is the machinery and tools needed in the process of stone mining, processing, decoration and other processes. Here we mainly briefly talk about the use of stone cutting machines. maintenance and maintenance.

1. Oil must be filled and changed in strict accordance with the lubrication requirements.

2. Regularly check whether the various fasteners are loose, and ensure that they are fastened. Any small negligence will lead to serious consequences; check the saw blade regularly: when it is found to be worn, replace it with a new saw blade in time

3. When replacing the diamond circular saw, the runout of the end face of the saw blade should be detected. The new saw blade should not exceed 0.8mm, and the rewelded saw blade should not exceed 1.5mm.

4. Regularly check whether the tension of the V-belt is moderate, whether there is slipping, and whether it is aging. If it is necessary, it should be adjusted or replaced.

5. Regularly check whether the centralized lubricating oil circuit is smooth.

6. Always check the electrical components in the control cabinet, whether the wiring screws are loose, and whether the action is sensitive. If any screw is loose, it should be tightened again immediately. Any small negligence will lead to serious consequences.

7. Whether the center of gravity is correct and stable when cutting the block, there must be 10~40mm left at the bottom of the block.

8. Regularly check whether there is water leakage in the spindle box. If found, the cause should be found out immediately, measures should be taken, and the oil should be changed again.

9. Regularly check whether all electrical appliances are safely grounded.

10. Regularly check whether the clearance of each motion guide rail is appropriate.

11. Maintenance of the motor: The coil of the motor of the stone cutting machine is the most important part of the motor. Check carefully whether the coil is damaged or not, and whether the cable is damaged.

12. Regularly clean up the sediment of the whole machine and sink.

1. Oil must be filled and changed in strict accordance with the lubrication requirements.

2. Regularly check whether the various fasteners are loose, and ensure that they are fastened. Any small negligence will lead to serious consequences; check the saw blade regularly: when it is found to be worn, replace it with a new saw blade in time

3. When replacing the diamond circular saw, the runout of the end face of the saw blade should be detected. The new saw blade should not exceed 0.8mm, and the rewelded saw blade should not exceed 1.5mm.

4. Regularly check whether the tension of the V-belt is moderate, whether there is slipping, and whether it is aging. If it is necessary, it should be adjusted or replaced.

5. Regularly check whether the centralized lubricating oil circuit is smooth.

6. Always check the electrical components in the control cabinet, whether the wiring screws are loose, and whether the action is sensitive. If any screw is loose, it should be tightened again immediately. Any small negligence will lead to serious consequences.

7. Whether the center of gravity is correct and stable when cutting the block, there must be 10~40mm left at the bottom of the block.

8. Regularly check whether there is water leakage in the spindle box. If found, the cause should be found out immediately, measures should be taken, and the oil should be changed again.

9. Regularly check whether all electrical appliances are safely grounded.

10. Regularly check whether the clearance of each motion guide rail is appropriate.

11. Maintenance of the motor: The coil of the motor of the stone cutting machine is the most important part of the motor. Check carefully whether the coil is damaged or not, and whether the cable is damaged.

12. Regularly clean up the sediment of the whole machine and sink.

Comentarios