-

Retrouver dansMembres

Retrouver dansMembres Retrouver dansVidéos

Retrouver dansVidéos Retrouver dansChaînes

Retrouver dansChaînes

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Cliquez iciPréférence de confidentialité

- Mots clés - #Vane Pumps

-

- Dernière mise à jour 23 septembre 2020 0 commentaire , 183 vues, 0 comme

- Taizhou, Zhejiang, China - Obtenir des directions

More from Cassidy vanepump

More in Politics

Related Blogs

Les archives

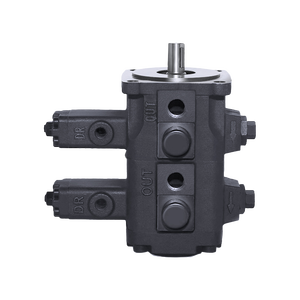

Several reasons for the failure of vane pump

Corps

In the use of Fixed Vane Pumps, some mistakes are often made but not easily noticed. Although there are detailed installation guidelines and precautions in the product manual, the incidence of errors is still high. These problems are basically caused by improper operation.

- Wrong installation of coupling:

Because the coupling gap between the coupling and the shaft is too small or there is no gap, the bearing will be injured when it is struck hard, resulting in early damage to the bearing and affecting the life of the entire pump core. Furthermore, if the coupling is installed without a certain amount of axial clearance, and the pump is directly mounted on the pump sleeve with screws, the bearing will be stressed in the axial direction. If the bearing is subjected to axial force for a long time, the bearing will be very It is about to damage and produce eccentricity and hit the pump core. On the surface, it looks like the pump core is out of order, but in fact, the initiator is the bearing.

- The oil is too dirty:

Because the fuel tank is not sealed, the surrounding dust and debris are mixed into the oil, causing the cleanliness of the oil to exceed the standard. If the filter accuracy is insufficient or there is no filter, the pump core will quickly be scratched and damaged.

Instant overpressure:

Very often, extreme accidents such as "back cover collapse", "front cover collapse", "broken shaft", "broken blade", and "split stator" occur in oil pumps. Simple judgments seem to be the quality of the oil pump. After careful analysis, it does have other reasons, such as: collapsed high pressure back cover and broken shaft or collapsed high pressure front cover and broken blades, broken stator, there is no connection between the door, this situation is actually caused by instantaneous overpressure When the internal pressure of the oil pump exceeds the pressure it can withstand, the weakest parts in the pump will be damaged, such as: the front and rear covers are broken, the blade is broken, the stator is broken, the shaft is broken, and the blade is broken and the stator is broken. Any one breaking first may cause another instant break. At the same time, other parts "rotor", "side plate" and "shaft" rotating at high speed will be passively damaged. Overpressure is the culprit of extreme accidents. The cause of the pressure of Vane Pumps is the blockage of the overflow valve.

Photos

Carte

-

Emplacements sur MyWorldGo

Information de Lieu

- Emplacement: Taizhou, Zhejiang, China - Obtenir des directions

- Adresse formatée: Taizhou, Zhejiang, China

- Adresse de rue: Taizhou

- Etat: Zhejiang

- Pays: China

commentaires