Appliance Test and Tagging: Ensuring Electrical Safety in the Workplace

Body

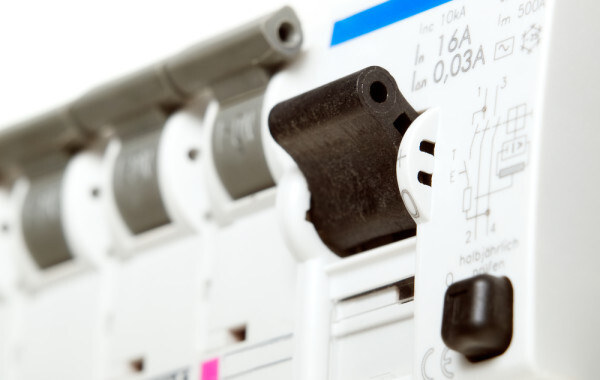

Electrical safety is a paramount concern in any workplace. To prevent accidents, injuries, and potential hazards, it is essential to regularly inspect and assess electrical appliances and equipment. Appliance Test and Tagging (PAT) is a systematic and efficient method used to ensure the rcd safety switch testing of electrical devices, and it has become an indispensable practice in modern workplaces.

What is Appliance Test and Tagging?

Appliance Test and Tagging is a process that involves inspecting, hydrant testing, and labeling electrical appliances and equipment to ascertain their safety. The main objective is to identify any potential electrical faults or defects that could pose a risk to users and take appropriate actions to mitigate those risks.

The process typically includes two key components:

- Visual Inspection: A visual examination is conducted to assess the physical condition of the appliance, its power cord, plug, and any associated cables. This initial inspection helps identify any visible damages, such as frayed cords or cracked casings.

- Electrical Testing: A series of electrical tests are performed using specialized Portable Appliance Testers (PAT) to evaluate the device's electrical integrity. These tests check for potential issues like insulation resistance, earth continuity, and polarity.

Why is Appliance Test and Tagging Important?

- Employee Safety: The primary reason for Appliance Test and Tagging is to ensure the safety of employees and anyone who uses electrical equipment within the workplace. Regular testing helps identify faulty appliances before they become potential hazards.

- Compliance with Regulations: Many countries and regions have specific safety regulations and standards that mandate the testing and tagging of electrical appliances. By adhering to these regulations, businesses can avoid legal liabilities and penalties.

- Risk Management: Implementing a comprehensive Appliance Test and Tagging program reduces the risk of electrical accidents, fire incidents, and damage to property. This, in turn, leads to fewer insurance claims and potential cost savings for businesses.

- Preventing Downtime: Electrical appliance failures can lead to significant downtime in a business's operations. Regular testing helps identify issues early on, allowing for timely repairs or replacements and minimizing disruptions to work.

- Public Image and Trust: Demonstrating a commitment to safety through regular testing can enhance a company's reputation and build trust among employees, customers, and business partners.

Conclusion

Appliance Test and Tagging is an essential process that ensures the safety of electrical appliances and equipment in workplaces. By conducting regular inspections and testing, businesses can reduce the risk of electrical accidents, comply with safety regulations, and protect their employees and assets. Investing in electrical safety not only prevents potential disasters but also reflects a responsible and caring attitude towards the well-being of everyone in the workplace.

Source URL :- https://sites.google.com/view/servicecorptestandtag-/home

Comments