Exploring the Efficiency and Applications of Monoblock Pumpsets

Body

Introduction:

In the realm of pumping systems, the monoblock pump set stands as a reliable and efficient solution for various fluid transfer needs. Its compact design, ease of installation, and versatility have made it a popular choice across residential, agricultural, and industrial settings. In this blog post, we'll delve into the intricacies of monoblock pumpsets, understanding how they work, their applications, and the benefits they offer.

Understanding Monoblock Pumps:

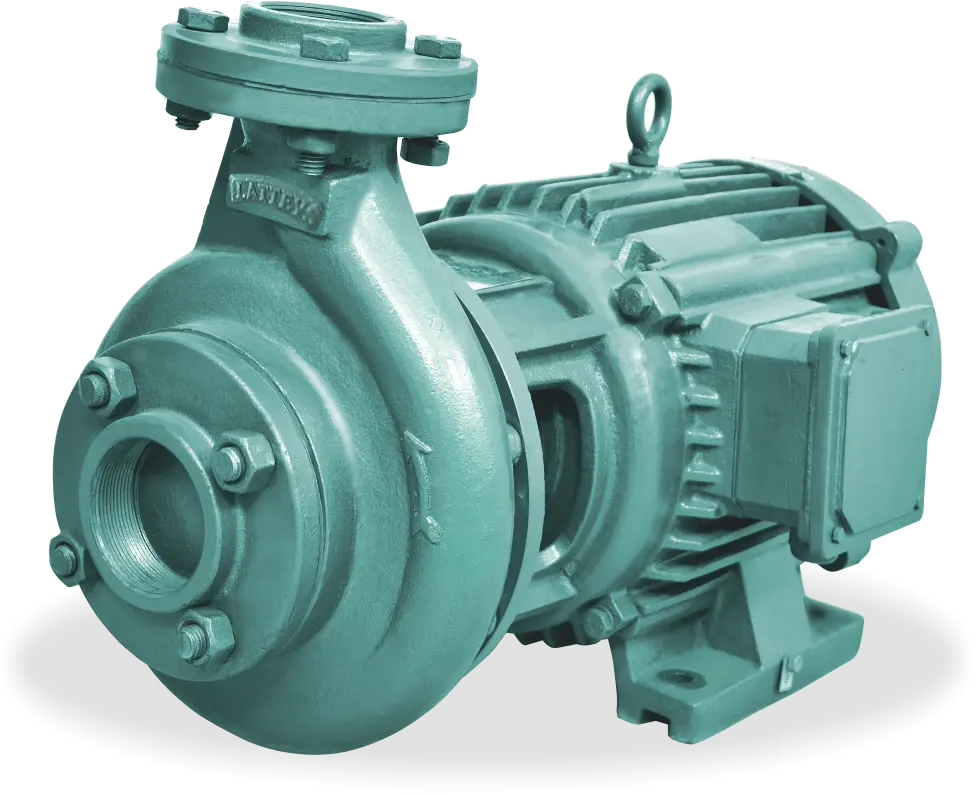

A monoblock pump, as the name suggests, is a single unit that houses both the pump and the prime mover (usually an electric motor) within a single casing. This eliminates the need for alignment between the pump and the motor, simplifying the installation process.Monoblock Pump 5hp are typically centrifugal pumps, designed to handle a variety of liquids, including water, chemicals, oils, and more.

Key Features and Advantages:

Compact Design: The integration of the pump and motor into a single unit results in a compact structure, making monoblock pumps ideal for installations where space is limited.

Easy Installation: Unlike split-case pumps that require careful alignment, monoblock pumpsets are relatively easier to install, reducing setup time and labor costs.

Low Maintenance: Monoblock pumps are designed for minimal maintenance. The single casing reduces the number of components that need maintenance or replacement.

Efficiency: These pumps are engineered for high efficiency and performance, ensuring effective fluid transfer while consuming less energy.

Cost-Effective: Due to their simplified design, monoblock pumps are often more cost-effective than other types of pumps, both in terms of initial investment and long-term maintenance.

Applications:

Domestic Water Supply: Monoblock pumps are commonly used in homes and residential complexes to supply water from wells, boreholes, or municipal sources to overhead tanks or storage systems.

Agriculture: They play a crucial role in agricultural irrigation, helping farmers water their fields efficiently and effectively.

Industrial Use: Monoblock pumps find applications in various industries, such as construction, manufacturing, and food processing, where fluid transfer is essential.

Swimming Pools: These pumps are utilized for circulating and filtering water in swimming pools and spa systems.

Commercial Buildings: In commercial complexes and offices, monoblock pumps are used for water circulation, cooling systems, and fire-fighting applications.

Choosing the Right Monoblock Pumpset:

When selecting a monoblock pumpset, several factors must be considered:

Flow Rate and Head: The required flow rate and head (vertical lift) should match the pump's specifications to ensure efficient operation.

Fluid Type: Choose a pump that is compatible with the type of fluid being transferred, whether it's water, chemicals, or other substances.

Motor Power: The pump's motor power should be appropriate for the intended application to avoid underperformance or overconsumption of electricity.

Reliability and Brand: Opt for reputable brands known for producing reliable and durable pumpsets.

Conclusion:

Monoblock pumpsets exemplify the harmony between simplicity and efficiency in fluid transfer systems. Their versatility, low maintenance requirements, and ease of installation make them a practical choice across various sectors. Whether it's for domestic water supply, agricultural irrigation, or industrial applications, the monoblock pumpset continues to play a vital role in meeting fluid transfer needs around the world.

Comments