A Detailed Look at Perforation Techniques in Well Completion

Corps

This article delves into the intricacies of perforation techniques, shedding light on the methods employed to optimize well completion for efficient resource extraction.

The Significance of Perforation

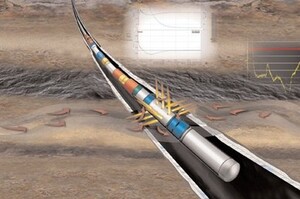

Perforation is the process of creating holes or channels in the well casing and surrounding formation to establish a connection between the reservoir and the wellbore. These perforations serve as pathways for hydrocarbons to flow into the wellbore, enabling extraction.

Understanding Well Completion: Well completion involves a series of steps to prepare a drilled well for production. This encompasses casing, cementing, and ultimately, perforating. The success of perforation significantly influences the well's overall productivity and efficiency.

Types of Perforation Techniques

Gun Perforation: This traditional method involves using perforating guns loaded with shaped charges. These guns are lowered into the well, and upon detonation, they create perforations in the casing and surrounding formation. Gun perforation is a well-established technique but may lead to damage to the near-wellbore area.

Jet Perforation: In this technique, high-pressure jets of fluid or abrasive material are used to create perforations. Jet perforation offers precision and control, minimizing damage to the reservoir. It is often favored in formations where conventional methods may pose challenges.

Explosive Tubing Cutter: This method involves the deployment of an explosive tubing cutter to create perforations. It provides a controlled and targeted approach, allowing for customization based on the reservoir's characteristics.

Key Considerations in Perforation

Perforation Density: The density and distribution of perforations play a crucial role in determining the well's productivity. Achieving an optimal balance is essential to maximize hydrocarbon flow while avoiding unwanted complications.

Formation Damage: During perforation, there is a risk of damaging the surrounding formation. Careful consideration of perforation parameters, such as charge size and phasing, helps mitigate potential damage and enhance reservoir connectivity.

Underbalance and Overbalance Conditions: Maintaining the right balance between wellbore pressure and reservoir pressure is critical. Underbalance conditions can lead to well damage, while overbalance conditions may result in formation damage. Perforation strategies are designed to address these considerations.

Technological Advancements in Perforation

Controlled Perforating Systems: Modern perforating systems incorporate advanced technology to precisely control the depth, phasing, and size of perforations. This level of control enhances reservoir connectivity and overall well performance.

Real-time Monitoring: Some perforation techniques now include real-time monitoring tools, allowing operators to assess and adjust perforation parameters during the process. This enhances decision-making and improves overall perforation outcomes.

Challenges and Future Trends

Formation Heterogeneity: Variability in reservoir characteristics poses challenges to achieving uniform perforation. Ongoing research focuses on developing techniques to address formation heterogeneity and optimize well completion.

Intelligent Perforation Systems: The industry is moving towards intelligent perforation systems that leverage data analytics and artificial intelligence to make informed decisions in real-time. These systems aim to enhance perforation accuracy and efficiency.

Conclusion

Perforation techniques are the linchpin of well completion, acting as the gateway for hydrocarbons to flow from the reservoir to the wellbore. As technology advances and the industry strives for greater efficiency, mastering perforation becomes paramount in unlocking the full potential of oil and gas reservoirs. By understanding and harnessing the nuances of perforation techniques, the oil and gas sector can pave the way for sustainable and optimized well production.

commentaires