Sticking Power Unveiled: The Dynamic World of Acrylic Adhesives in Modern Manufacturing

Cuerpo

In the sizable realm of adhesives, one class sticks out for its extraordinary versatility and robust bonding abilities – Acrylic Adhesives. These adhesives are tuning into crucial in various industries, because of their particular features and various applications.

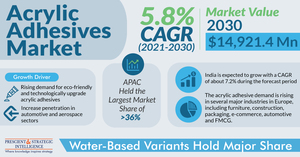

The acrylic adhesives market is witnessing growth and is projected to reach USD 14,921.4 million by 2030.

Composition and Characteristics:

Acrylic adhesives are polymers made by the polymerization of acrylic or methacrylic ester monomers. The resulting adhesive gives a combination of perfect tendencies, making it a favored choice for many works. One key characteristic is their capacity to provide excessive-strong bonds on an extensive range of substrates, such as metals, plastics, glass, and composites.

These adhesives are known for their outstanding resistance to environmental factors together with moisture, warmness, and chemical substances. The durability of acrylic adhesives guarantees long-lasting bonds, making them appropriate for applications in diverse conditions. Additionally, they showcase exact UV resistance, making them perfect for outdoor applications wherein exposure to sunlight is a concern.

Versatile Applications:

Automotive Industry:

Acrylic adhesives play a crucial role in the car industry, where they're used for bonding numerous additives. From attaching trim and symbols to bonding interior panels, acrylic adhesives provide a sturdy and dependable solution. Their capability to withstand severe temperatures and harsh situations makes them precious in car production.

Construction Sector:

In the construction industry, acrylic adhesives were discovered to work in bonding structural elements, panels, and insulation substances. Their versatility allows for bonding specific sorts of surfaces, contributing to the strength and integrity of diverse structures. The brief curing time of a few acrylic adhesives is an introduced benefit in manufacturing tasks with tight timelines.

Electronics and Aerospace:

Acrylic adhesives are extensively used in the electronics and aerospace industries because of their electrical insulation residences and capability to bond diverse materials. They are instrumental in the production of electronic gadgets and components, ensuring dependable connections and greater overall performance.

Medical Devices:

In the scientific area, where precision and biocompatibility are paramount, acrylic adhesives are employed within the assembly of medical gadgets. Their capacity to bond plastics and other substances without compromising biocompatibility makes them a favored preference for medical applications.

Acrylic adhesives have absolutely turned out to be the unsung heroes of modern-day manufacturing, contributing to the strength, durability, and efficiency of an extensive variety of products. From automotive applications to creation tasks and scientific gadgets, those adhesives have proven their worth across diverse industries.

Comentarios