More from YSmarines YSmarines

More in Politics

Related Blogs

Archives

Social Share

What are Effective Methods for Defect Detection and Categorization in Printed Materials

Body

Ensuring the quality of printed materials is paramount across various industries, where defects can compromise both aesthetics and functionality. Modern technology has introduced sophisticated solutions to tackle this challenge, offering comprehensive methods for defect detection and categorization in printed materials.

The Significance of Quality Assurance in Printed Materials

Whether it's packaging, labels, newspapers, or industrial components, defects in printed materials can have severe consequences. Even minor imperfections can render products unsellable or compromise their performance. Therefore, robust quality assurance processes are essential to identify and rectify defects in the printing industry.

Common Detection Techniques

Visual Inspection

Human Visual Inspection: Trained operators visually inspect printed materials for visible defects like misprints, smudges, and color inconsistencies.

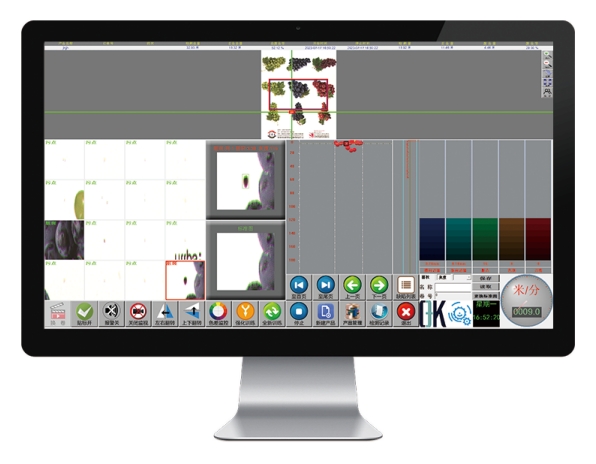

Automated Optical Inspection (AOI)

Automated vision print inspection system utilizes high-resolution cameras and advanced image processing algorithms for rapid and automated defect detection.

Machine Vision Systems

Equipped with cameras and sensors, coupled with image analysis software to identify defects such as misprints, color variations, and scratches.

UV Inspection

Illuminates printed materials with ultraviolet light to reveal defects like ink splatters, stains, and contamination that may not be visible under normal lighting.

Spectrophotometry

Measures color properties to ensure consistency and detect color inconsistencies across printed materials.

Dimensional Measurement

Uses tools like calipers and micrometers to ensure printed materials meet specified dimensional tolerances.

Barcodes and QR Codes Inspection

Verifies the accuracy and readability of printed codes for product identification and inventory management.

Surface Inspection Technologies

Employs microscopy techniques to identify surface defects like scratches, abrasions, and printing artifacts.

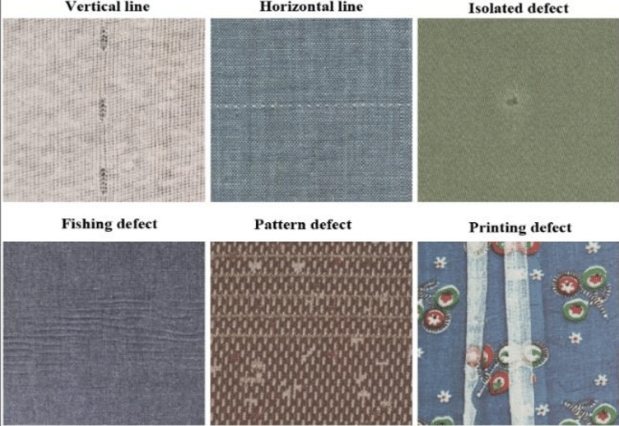

Categorization Methods for Printed Materials

Defects are categorized based on type, severity level, location, frequency, root cause, impact on functionality, customer impact, and corrective action required.

Technological Advancements

Real-Time Monitoring and Feedback Systems

Provides continuous monitoring, immediate feedback, and data analytics for proactive quality management.

Artificial Intelligence (AI) and Machine Learning

Utilizes advanced algorithms for automated defect categorization and continuous improvement in detection accuracy.

Remote Inspection Technologies

Enables real-time monitoring and collaboration from remote locations through cloud-based solutions and collaborative tools.

Integration with Industry 4.0 and IoT

Enhances connectivity, data exchange, and smart manufacturing practices for improved efficiency and quality in printing operations.

Conclusion

Detecting and categorizing defects in printed materials are critical processes for maintaining quality standards and customer satisfaction in the printing industry. Leveraging advanced inspection technologies, automated systems, and collaborative approaches ensures efficient defect detection and categorization, ultimately contributing to the success of printing operations. Continuous improvement driven by technological advancements further enhances the effectiveness of quality assurance processes in printed materials.

Comments