-

Encontrar enMiembros

Encontrar enMiembros Encontrar enVideos

Encontrar enVideos Encontrar enCanales

Encontrar enCanales

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy haga clic aquíPreferencia de privacidad

- Etiquetas - #BLOG

-

- Última actualización 1 de mayo de 2024 0 comentarios, 72 vistas, 0 likes

More in Politics

Related Blogs

Archivo

Exploring the Latest Technological Innovations in CNC Machinery

Cuerpo

The Evolution of CNC Machinery

Over the years, CNC machinery has undergone a remarkable transformation, revolutionizing the manufacturing industry. The integration of advanced technologies such as artificial intelligence, machine learning, and IoT has propelled CNC machinery to new heights of precision, efficiency, and automation. These innovations have not only enhanced the capabilities of CNC machines but have also expanded the scope of what can be achieved in manufacturing.

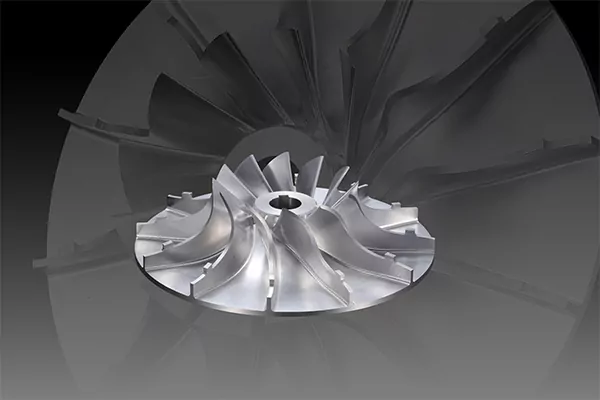

Advancements in Precision Engineering

The latest technological innovations in CNC machinery have significantly improved precision engineering. High-speed machining, multi-axis capabilities, and advanced tooling systems have enabled manufacturers to achieve intricate and complex geometries with unparalleled accuracy. The use of advanced sensors and real-time monitoring systems has further enhanced the precision of CNC machining processes, ensuring consistent quality and dimensional accuracy in the production of components.

Enhanced Automation and Efficiency

Automation has been a key focus of the latest technological innovations in CNC machinery. The integration of robotic arms, automated tool changers, and adaptive control systems has streamlined manufacturing operations, reducing manual intervention and minimizing production lead times. Additionally, the implementation of predictive maintenance technologies has optimized machine uptime and productivity, allowing cnc manufacturing shops to operate with maximum efficiency.

The Impact of Additive Manufacturing

One of the most groundbreaking innovations in CNC machinery is the integration of additive manufacturing processes. The combination of traditional subtractive machining with additive techniques such as 3D printing has unlocked new possibilities in part design and production. This hybrid approach allows for the creation of complex, lightweight structures with reduced material waste, opening doors to innovative applications in aerospace, medical, and automotive industries.

As CNC machinery continues to evolve, it is essential for manufacturing professionals to stay abreast of the latest technological advancements and embrace the opportunities they present. The convergence of digitalization, automation, and additive manufacturing is reshaping the future of CNC manufacturing, offering unprecedented levels of flexibility, customization, and productivity.

Comentarios