-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

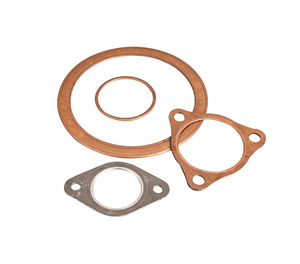

- Tags - #Spiral Wound Gaskets For Sale,Metal Jacketed Gaskets Manufacturers

-

- Last updated May 24, 2021 0 comments, 115 views, 0 likes

More from xinjia shaoxing

More in Politics

Related Blogs

Archives

Stress relaxation of gasket material

Body

Stress relaxation of gasket material

The performance of Spiral Wound Gaskets of Metal Jacketed Gaskets Manufacturers is directly related to the stress retention capability of the gasket material. When the material rots or becomes brittle or soft, the stress relaxation of the material will be impaired, so its ability to withstand pressure will also be impaired. Generally, the shelf life of rubber-based materials is 7 years. In critical applications, it is important to ensure that rubber-based materials are used within their shelf life. If required, we can provide materials or parts with batch numbers and curing dates so that customers can ensure that only gaskets that will not fail due to material deterioration are installed.

Gasket material thickness and pressure

Generally, the thinnest gasket material that is applicable should be selected. This is because the thinner material has a surface area (smallest ID or inner diameter) to which pressure can be applied, so it is less likely to malfunction. That being said, the choice of material thickness also needs to take into account the amount of compression required to withstand any flange deformation or misalignment-especially when using fiber-based gasket materials.

Flange quality and pressure

The finish of the metalwork on the flange is critical to the proper sealing of joints using Spiral Wound Gaskets. The surface finish should not be too rough, otherwise, a leakage path will be formed under the gasket. Standard pipe flanges usually have a groove on the sealing surface, and the gasket will deform under pressure. This also helps to limit the displacement of the gasket on the flange surface. Before reinserting the gasket, fix the flange damage. The mating flange should be made of the same material and processed the same to make the pressure evenly distributed on the surface of the bolt and flange.

Spiral Wound Gaskets For Sale is also our product, welcome to consult and purchase.

Comments