How Surface Energy Affects Wetting Behavior and Adhesive Properties in Materials

الجسم

Surface energy is a fundamental property of materials that describes the disruption of intermolecular bonds that occurs when a surface is created. It plays a critical role in determining how a liquid interacts with a solid surface. Understanding surface energy is essential for predicting wetting behavior and adhesive properties, which are crucial in various applications, including coatings, adhesives, and material design.

The Concept of Wetting

Wetting refers to the ability of a liquid to Surface Energy Measurement contact with a solid surface, influenced by the adhesive forces between the liquid and the solid, as well as the cohesive forces within the liquid. The degree of wetting is characterized by the contact angle formed between the liquid and the solid surface. A low contact angle indicates good wetting, while a high contact angle suggests poor wetting. Surface energy significantly influences this behavior.

Surface Energy and Contact Angle

The relationship between surface energy and contact angle is governed by Young's equation, which relates the contact angle to the surface tensions of the solid, liquid, and their interface. Materials with high surface energy tend to have lower contact angles, indicating better wetting behavior. Conversely, materials with low surface energy exhibit higher contact angles, leading to poor wetting. This relationship is crucial for applications where liquid spreading is desired.

Impact on Adhesive Properties

Surface energy also plays a vital role in determining the adhesive properties of materials. Adhesion occurs when two surfaces come into contact, and the strength of this bond is influenced by the surface energy of the materials involved. High surface energy materials typically exhibit better adhesive properties due to their ability to form stronger intermolecular interactions. In contrast, low surface energy materials may struggle to achieve strong adhesion, resulting in weaker bonds.

Applications in Coatings and Paints

Understanding the relationship between surface energy, wetting behavior, and adhesive properties is essential in the formulation of coatings and paints. High-performance coatings require good wetting to ensure uniform application and adhesion to surfaces. By manipulating the surface energy of the substrate or the coating material, manufacturers can optimize performance, enhancing durability and resistance to environmental factors.

Role in Material Design

In material design, surface energy considerations are crucial for developing products with specific wetting and adhesive properties. For instance, in biomedical applications, materials with tailored surface energies can enhance biocompatibility and promote cell adhesion. Similarly, in the automotive and aerospace industries, optimizing surface energy can improve the performance of adhesives and coatings, leading to more reliable and efficient products.

Influence of Surface Modifications

Surface modifications can significantly alter the surface energy of materials, thereby affecting their wetting behavior and adhesive properties. Techniques such as plasma treatment, chemical etching, and the application of surfactants can increase or decrease surface energy. These modifications enable the customization of material properties for specific applications, allowing for improved performance in various environments.

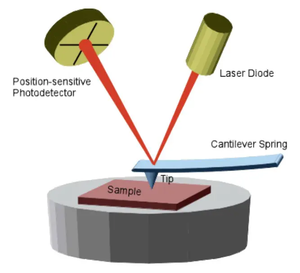

Challenges in Measuring Surface Energy

Measuring surface energy accurately can be challenging due to the complexity of interactions at the molecular level. Various methods exist for determining surface energy, including contact angle goniometry and the use of probe liquids. However, each method has its limitations, and results can vary based on environmental conditions and the nature of the materials being tested. Understanding these challenges is essential for interpreting measurement results accurately.

Future Directions in Surface Energy Research

The study of surface energy and its effects on wetting behavior and adhesive properties is an evolving field. Future research may focus on developing advanced materials with tailored surface energies for specific applications. Additionally, the integration of nanotechnology and surface engineering techniques holds promise for creating innovative solutions that enhance performance in various industries.

Conclusion

In conclusion, surface energy is a critical factor influencing wetting behavior and adhesive properties in materials. Understanding this relationship is essential for optimizing performance in applications ranging from coatings to material design. By manipulating surface energy through various techniques, researchers and manufacturers can develop materials with enhanced properties, leading to improved functionality and reliability in diverse applications

تعليقات