The Benefits of High Output Vapor Tight LEDs for Cold Storage Environments

Body

The Benefits of High Output Vapor Tight LEDs for Cold Storage Environments

In the realm of cold storage, maintaining optimal conditions is crucial for preserving perishable goods. One of the most effective ways to achieve this is through the use of high output vapor tight LEDs for cold storage. These specialized lighting fixtures not only enhance visibility but also contribute to energy efficiency and safety. In this article, we will delve into the numerous benefits of these innovative lighting solutions.

Understanding High Output Vapor Tight LEDs

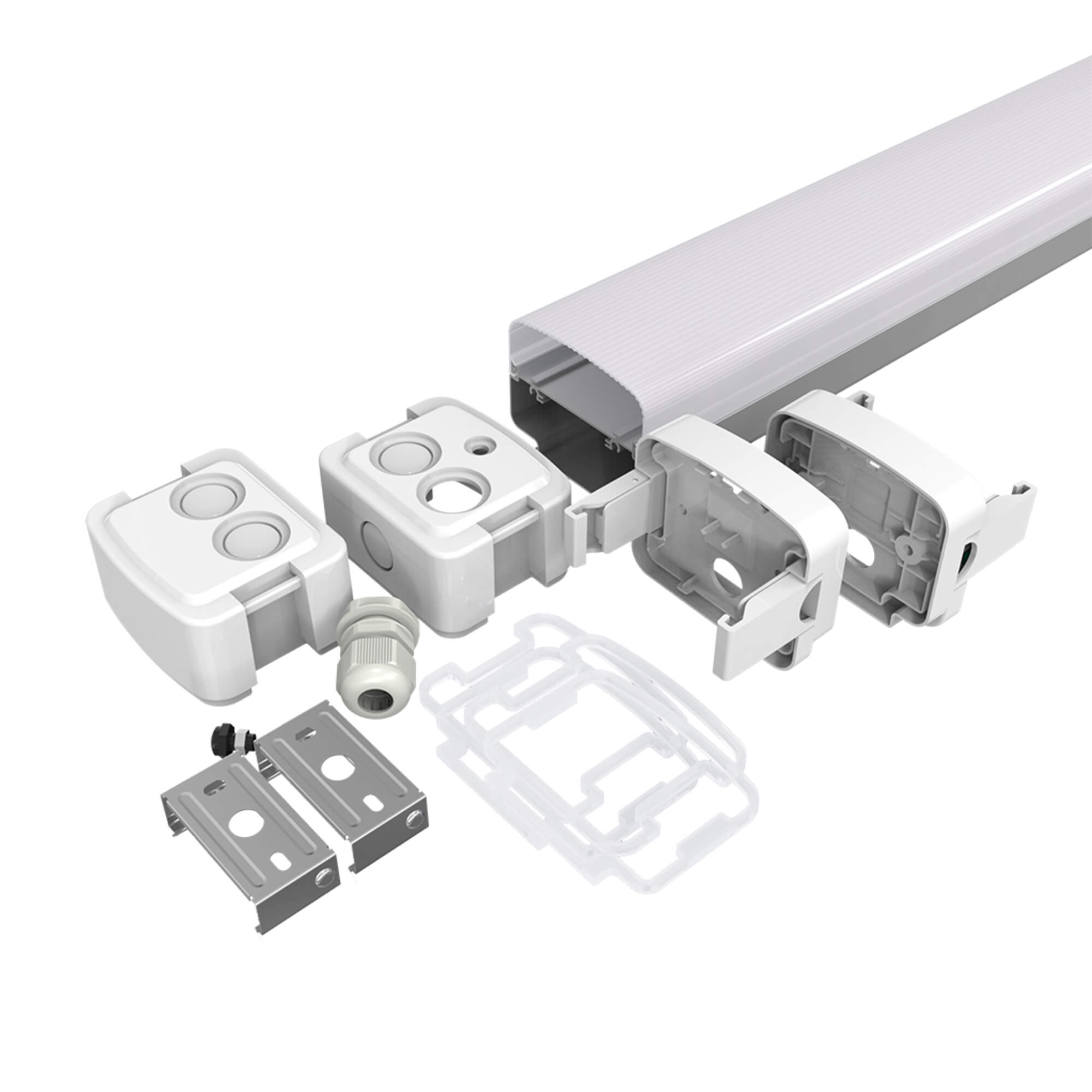

What exactly are high output vapor tight LEDs for cold storage? These fixtures are designed to withstand harsh environments, including extreme temperatures and humidity levels. Their robust construction ensures that they remain operational in conditions that would typically damage standard lighting options. Furthermore, their high output capability means they provide bright, consistent illumination, which is essential for visibility in cold storage facilities.

Energy Efficiency and Cost Savings

One of the most significant advantages of using high output vapor tight LEDs for cold storage is their energy efficiency. Compared to traditional lighting solutions, LEDs consume significantly less power while delivering the same or even greater light output. This reduction in energy consumption translates to lower electricity bills, making them a cost-effective choice for businesses.

- Long lifespan: LEDs can last up to 50,000 hours, reducing the frequency of replacements.

- Lower heat emission: LEDs produce minimal heat, which is crucial in cold storage environments.

- Instant illumination: Unlike fluorescent lights, LEDs provide immediate brightness without flickering.

Durability and Reliability

Cold storage facilities often face challenging conditions, including moisture and temperature fluctuations. High output vapor tight LEDs for cold storage are specifically engineered to resist these elements. Their sealed design prevents moisture and dust ingress, ensuring long-term reliability. This durability means fewer maintenance issues and reduced downtime, allowing businesses to operate smoothly.

Safety and Compliance

Safety is paramount in any storage environment. The use of high output vapor tight LEDs for cold storage enhances safety by providing bright, clear lighting that reduces the risk of accidents. Additionally, many LED fixtures are compliant with safety regulations, ensuring that businesses meet industry standards. This compliance is essential for maintaining a safe working environment for employees.

Conclusion

In conclusion, the adoption of high output vapor tight LEDs for cold storage offers numerous benefits, including energy efficiency, durability, and enhanced safety. As businesses strive to improve their operations and reduce costs, these lighting solutions present an ideal option. For more information on high-quality vapor tight LED fixtures, visit  .

.

By investing in high output vapor tight LEDs for cold storage, companies can ensure that their facilities are well-lit, safe, and energy-efficient, ultimately leading to improved productivity and reduced operational costs.

Comments