Uncover the Ultimate Guide to Choosing the Perfect Vapor Tight LED Lighting!

In today's world, where lighting plays a crucial role in safety and functionality, vapor tight LED lighting stands out as a reliable solution for various environments, especially industrial and outdoor settings. These fixtures are specifically designed to withstand moisture, dust, and chemicals, making them ideal for use in locations such as warehouses, manufacturing plants, tunnels, and parking garages. Choosing the right vapor tight LED lighting can greatly impact the efficiency and safety of these spaces. With options ranging from energy-efficient models to robust designs, it's essential to make an informed choice that aligns with your specific needs. This guide will help you navigate through the various types of vapor tight LEDs available, highlighting their features, benefits, and practical tips for installation and maintenance.

Understanding Vapor Tight LED Lighting

Vapor tight LED lighting is designed to protect the light source from moisture and particulates, ensuring reliable performance in challenging environments. These fixtures are typically sealed with gaskets and are constructed from durable materials, making them resistant to corrosion and impacts. Common applications include food processing facilities, chemical plants, and outdoor areas exposed to weather elements. The necessity for vapor tight fixtures arises from the potential hazards posed by moisture and dust, which can lead to electrical failures and safety risks. By utilizing vapor tight LEDs, industries can enhance their safety protocols while also benefiting from energy efficiency and reduced maintenance costs. For instance, a friend of mine who works in a food processing plant shared how switching to vapor tight LED fixtures not only improved visibility but also reduced the number of lighting failures due to the humid environment, ultimately increasing productivity.

Key Features to Look for in Vapor Tight LEDs

When evaluating vapor tight LED lighting options, several key features should be prioritized to ensure optimal performance. First, consider the lumens per watt output, which indicates the efficiency of the fixture in converting electrical energy into light. Higher lumens per watt translate to brighter lighting while consuming less power. Additionally, color temperature affects the ambiance and functionality of the space—cooler temperatures are often preferred for work environments, while warmer tones may be more suitable for recreational areas. Durability ratings such as IK (impact protection) and IP (ingress protection) are crucial as they signify the fixture's resistance to physical damage and environmental factors. Energy efficiency is another vital aspect, as it directly impacts operating costs over time. Lastly, the lifespan of the LEDs should be a consideration, as longer-lasting fixtures reduce replacement frequency and maintenance efforts. Understanding these features can significantly aid in selecting the right vapor tight LED that meets specific application needs.

Comparing Different Vapor Tight LED Options

When it comes to selecting vapor tight LED lighting, a variety of options are available, each with distinct characteristics that cater to different needs. For instance, some fixtures may offer a sleek, low-profile design ideal for tight spaces, while others may be bulkier but provide enhanced durability for extreme conditions. Installation ease is another critical factor; some models feature plug-and-play designs that simplify the setup process, while others may require more complex wiring. Maintenance requirements can vary as well, with some fixtures allowing for easy access to components for quick repairs or bulb replacements. Performance metrics, such as light distribution and color rendering index (CRI), also play a role in how effectively the lighting serves its intended purpose. A friend who manages a warehouse found significant differences in performance when he compared a few options side by side, noting that one model provided even light distribution, which improved visibility across the entire space. Evaluating these factors against specific needs ensures a well-informed decision when choosing vapor tight LED lighting.

Installation and Maintenance Tips

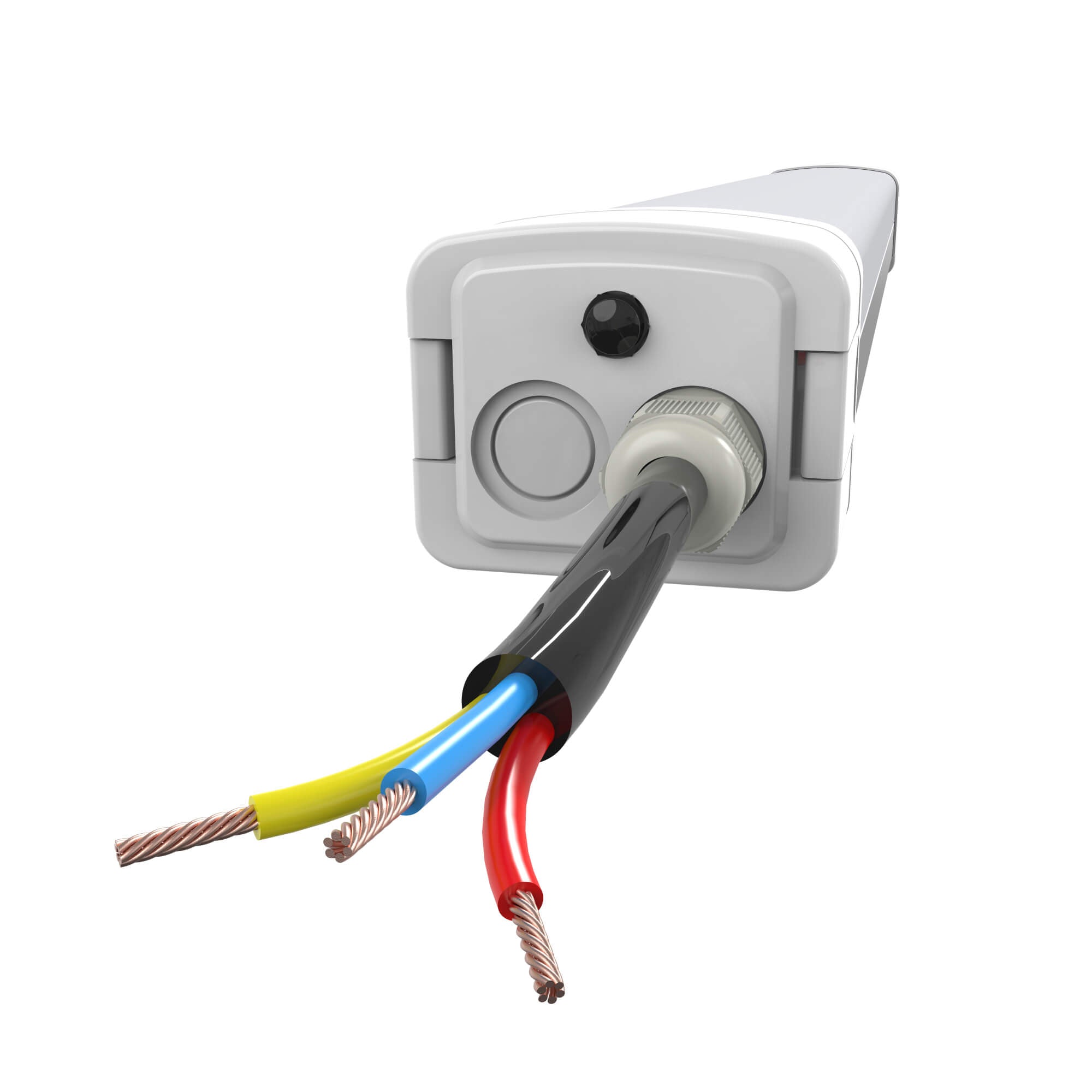

Installing vapor tight LEDs involves a few key considerations to maximize their effectiveness. First, assess the placement of fixtures to ensure even light coverage, particularly in larger spaces. Proper wiring is essential, so consult with a professional if you're unsure about electrical connections. It's also important to consider the height of installation; fixtures mounted too high may not provide sufficient illumination for tasks below. Once installed, regular maintenance checks should be performed to ensure the integrity of seals and gaskets, as these are critical in maintaining the vapor tightness of the fixture. Regularly cleaning the lenses can also help maintain light output and clarity. By following these installation and maintenance tips, you can ensure that your vapor tight LED lighting remains effective and long-lasting.

Summary of Key Takeaways

In summary, understanding the features and functionalities of vapor tight LED lighting is essential for making informed decisions that enhance the safety and efficiency of various environments. By considering factors such as lumens per watt, durability ratings, and installation ease, you can select the best option tailored to your specific needs. With the right choice, vapor tight LEDs can significantly improve visibility, reduce energy costs, and minimize maintenance efforts. Whether you're outfitting a warehouse or an outdoor area, taking the time to evaluate your lighting requirements will lead to a successful and satisfying purchase.

Comments