Unlock the Secrets to Finding Reliable GE Electric Parts Suppliers!

Finding reliable suppliers for GE electric parts is crucial for anyone involved in industrial applications, maintenance, or electrical installations. The integrity and performance of electric systems can hinge on the quality of the components used. Poor-quality parts not only compromise operational efficiency but can also pose significant safety hazards. However, sourcing quality parts can be a daunting task due to the sheer number of suppliers and variations in product quality. This article aims to guide you through the essential steps to identify trustworthy suppliers for GE electric parts, helping you make informed purchasing decisions that ensure safety and performance.

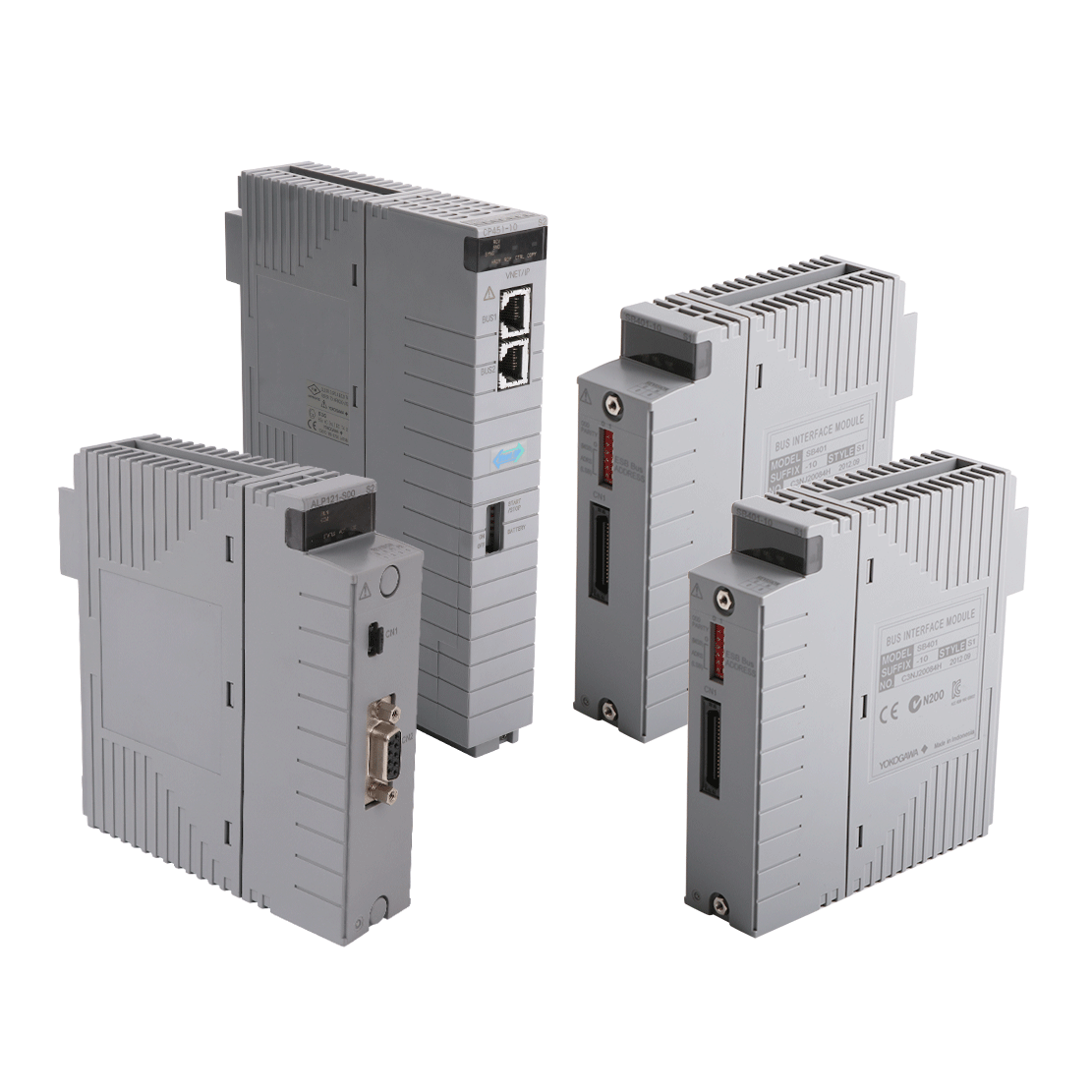

Understanding GE Electric Parts

GE electric parts encompass a wide range of components used in various electrical systems, from circuit breakers to transformers and control panels. These parts are integral to industries such as manufacturing, energy, and construction, where reliability is non-negotiable. The performance of your electrical installations often depends on the quality of these parts, as they directly affect efficiency and safety. Essential criteria for assessing the quality and reliability of electric parts include their durability, compliance with industry standards, and the reputation of the manufacturer. A friend of mine, who works in a manufacturing plant, once shared how a single faulty part led to a major operational halt, underscoring the importance of sourcing reliable components.

Factors to Consider When Choosing Suppliers

When selecting suppliers for GE electric parts, several key factors should be taken into consideration. First and foremost is the supplier's reputation within the industry; a well-regarded supplier is often a reflection of quality and reliability. Additionally, assess the product range they offer—having access to a variety of parts can simplify your supply chain. Warranty policies are also crucial; a supplier that stands behind their products with robust warranties demonstrates confidence in their offerings. Customer service is another vital aspect; suppliers that provide responsive and knowledgeable support can make your purchasing experience smoother. It's wise to conduct thorough research on potential suppliers before making a commitment, which can save you time and money in the long run.

Where to Find Reliable Suppliers

Identifying reliable suppliers for GE electric parts involves exploring various sources. Online directories can be a great starting point; they often list suppliers along with reviews and ratings from previous customers. Trade shows present an excellent opportunity to meet suppliers face-to-face, allowing you to establish personal connections and view products up close. Industry publications also regularly feature supplier listings and advertisements, making them a valuable resource. Networking opportunities within your industry can lead to recommendations for reputable suppliers. For instance, during a recent industry conference, I learned about a lesser-known supplier praised by several attendees for their exceptional quality and service.

Evaluating Potential Suppliers

Once you have a list of potential suppliers, the next step is to evaluate them effectively. Start by checking customer reviews and testimonials, which can provide insights into the experiences of other buyers. Requesting samples of the parts you need can also be a crucial step; this allows you to assess quality firsthand before making a bulk purchase. Additionally, verifying the supplier's certifications and understanding their manufacturing processes can provide further assurance of their reliability. A friend of mine once emphasized the importance of this step after his company faced issues with a supplier that lacked proper certifications, leading to costly delays.

Building Long-Term Relationships with Suppliers

Establishing a solid relationship with your suppliers can yield numerous benefits. A good relationship fosters effective communication, ensuring that your needs are understood and met promptly. Regularly engaging with your suppliers can lead to better pricing, priority service, and access to new products before they become widely available. Strategies for nurturing these relationships include open and honest communication, providing feedback, and recognizing their contributions to your success. Building rapport with suppliers can transform a transactional relationship into a collaborative partnership that benefits both parties.

Ensuring Quality and Reliability in Supplier Relationships

In conclusion, sourcing reliable suppliers for GE electric parts is essential for ensuring the performance and safety of your electrical installations. By understanding the importance of quality parts, considering key factors when selecting suppliers, exploring various sourcing avenues, and evaluating potential suppliers diligently, you can make informed decisions that will benefit your projects. Moreover, fostering long-term relationships with your suppliers can enhance your supply chain efficiency and open doors to future opportunities. Take proactive steps today in your search for quality suppliers, and secure the success of your electrical systems.

Comments