Choosing a CNC Machining Cooling Method - Which one should you use

الجسم

It is possible to use the term computer numerical control (CNC) machining to refer to any computer-automated tool control, such as spark cutting, water jet cutting, or plasma cutting. As a result of its relative simplicity, mechanical simplicity, and low cost, milling has remained the most commonly encountered CNC process in industry for many years. Although CNC milling has a competitive advantage over other machining techniques, a number of mechanical, electrical, and material-related failure modes have caused it to lose that advantage. Notably, overheating of the rotary cutters or milled materials has the potential to permanently damage the milling device as well as cause bodily harm to the operators of the machine. A variety of manufacturing techniques have been developed to control the amount of heat produced while keeping costs as low as possible in CNC processes to reduce the likelihood of mill overheating. It is the purpose of this article to summarize the most significant advancements in overheating mitigation for metal CNC machining.

Cooling by flooding

Flood cooling, also known as wet cooling, is one of the most commonly used cooling techniques. It involves spraying a constant jet of coolant onto the contact area between the tool and the milled material in order to cool the tool and the milled material. It is a very safe and effective method of heat mitigation that is also extremely cost-effective. Furthermore, the spray of coolant has the additional benefit of washing away chips of material produced during the milling process from the workpiece's contact area. One disadvantage is the high cost of cooling fluid, as well as the wayPrecision Machining spreads inside and outside the machine, necessitating more cleanup. Furthermore, synthetic cooling fluid is frequently toxic and can generate particles that are hazardous to the environment and human health.

Solid lubrication is used in a variety of applications.

Strong metalworking liquids, such as industrial ointments, can be used to replace less viscous liquids in a variety of applications. When mineral-based cooling liquids are used in flood cooling, they have the potential to contaminate water and soil. Solid lubrication is more environmentally friendly than flood cooling because it requires less fluid than flood cooling. It is also more cost-effective than flood cooling in many cases. Unfortunately, lubricant delivery is less efficient and less frictionless than a constant spray system, necessitating the application of lubricant to the contact area on a regular basis. Furthermore, solid lubrication is not recommended for applications that require the removal of material chips in a short period of time.

Minimum quantity lubrication (MQL) is a machining technique that aims to use the smallest amount of cutting liquid possible during the machining process.

As a result of the high volume of coolant required for flood cooling, which increases both the cost and environmental impact of the machining process, MQL seeks to reduce these factors by tailoring the coolant requirements to the specific requirements of a process. As a result, MQL processes must be designed with greater precision, because a calculation error could have catastrophic consequences for the machine or its operators.

Compressed air is used in many applications.

The use of minimal lubrication, such as MQL or solid lubrication, can significantly reduce the amount of cooling agent required. It is possible to completely eliminate the need for lubricant, alleviating the problems associated with disposal and variable costs. Using compressed air to cool and clear chips from a CNC machining process may very well be the most cost-effective and time-efficient method of doing so. Unfortunately, because compressed air cooling lacks lubricating properties, it is inapplicable to processes that involve a great deal of friction and heat transfer.

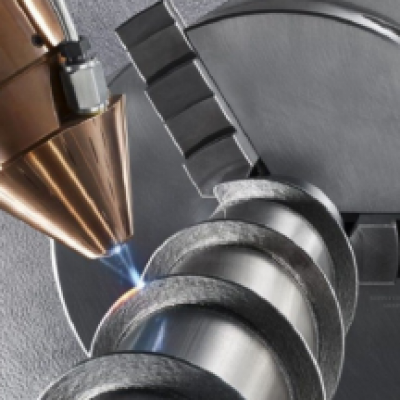

The use of cryogenic cooling

To keep the milling surface cool whilePrecision Machining is being used, liquid nitrogen can be injected into the tool during the process. Evidence has shown that this method produces a more even finished surface than flood cooling, and that the injected tools have a longer life cycle than their more conventional counterparts, both of which are beneficial. In light of the fact that it has relatively low variable costs due to the fact thatPrecision Machining Services does not require a large quantity of flood coolant, it is a viable option for applications in which the application of exterior coolants is not practical.

Which method is the most effective?

There is no single method that is superior to all of the others. According to the specific context in which CNC milling is required, each method has advantages and disadvantages that can add value to a process depending on the specifics of the situation. It is critical to remember that selecting the most appropriate method for preventing overheating must be done first and foremost with the safety of the operators in mind. Many jurisdictions have regulations for machining processes, which undoubtedly has an impact on the decision on which cooling method to use.

تعليقات