-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Metal Forging

-

- Last updated March 28, 2022 0 comments, 164 views, 0 likes

- VCA TLC Animal Hospital, Santa Monica Boulevard, West Hollywood, CA, USA - Get Directions

More from china mfg

More in Politics

Related Blogs

Archives

Body

Free forging

It is the oldest type of industrial forging and is characterized by the deformation of metal not limited by its shape or mass (it is free). It is used to manufacture usually larger single or small batches. Furthermore, such metal forgings are used to prepare preforms for die forging.

It can also be found as a forge in open dies.

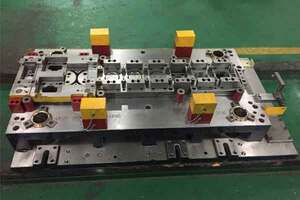

Before and after applying the die forging process

This type of forging service involves placing a part between two dies which, when closed, form a cavity with the desired shape and size of the part. As the process progresses, whether using a hammer or a press, the material deforms and adapts to the die until the desired geometry is achieved. This process must be performed with burr beads to provide the necessary pressure when filling the final area of the workpiece, especially if the part has a small radius and can be free of burrs, depending on whether the mold contains a release area that accommodates excess material (burrs) . It is used to manufacture large series of parts that vary widely in size and geometry. The pieces range in size from a few millimeters in length to several meters and tons in weight, and their geometry can be simple or complex.

It can also be found as a forging in closed dies.

Isothermal Forging

Main article: Isothermal forging.

Isothermal forging is a special type of forging in which the temperature of the die is significantly higher than that used in traditional china forging manufacturer. depressed

Unlike the previous process performed hot, this process can also be performed cold. It consists of the concentration or accumulation of material in a certain and limited area of a piece (usually in strips). Therefore, a direct consequence of this process is that the length of the initial bar decreases, while its cross-section in the upset zone increases.

If the process is carried out cold, and at the end of the workpiece, it is called cold heading.

Photos

Map

-

Locations on MyWorldGo

Location Information

- Location: VCA TLC Animal Hospital, Santa Monica Boulevard, West Hollywood, CA, USA - Get Directions

- Formatted Address: 8725 Santa Monica Blvd, West Hollywood, CA 90069, USA

- Street Address: 8725,Santa Monica Boulevard,Central LA,West Hollywood

- City: Los Angeles County

- Zipcode: 90069

- State: California

- Country: United States

Comments