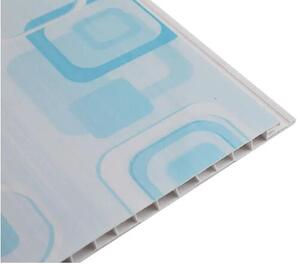

- الكلمات - #UV print pvc board PVC celuka board

-

- آخر تحديث ٢٠ يونيو، ٢٠٢٢ تعليق ٠ , ٢٤٧ views, ٠ مثل

More from pai ou

More in Politics

Related Blogs

أرشيف

How To Avoid Degradation Of PVC Board Type Materials

الجسم

PVC is a heat-sensitive plastic with poor light stability. Under the action of heat and light, it is prone to de-HCl reaction, which is commonly referred to as degradation. The result of degradation is that the strength of plastic products is reduced, discolored, and black lines appear, and in severe cases, the products lose their use-value. Factors affecting the degradation of PVC include polymer structure, polymer quality, stabilization system, molding temperature, and so on. According to experience, the yellowing of PVC board type materials is mostly due to the presence of paste at the die. The reason is that the die flow channel is unreasonable or the local polishing in the flow channel is not good, and there is a stagnation area. Most of the yellow lines of PVC profiles are pasted into the barrel. The main reason is that there are dead corners between the sieve plates (or transition sleeves), and the material flow is not smooth. If the yellow line is longitudinally straight on the PVC profile, the stagnation material is at the exit of the die; if the yellow line is not straight, it is mainly in the transition sleeve. The yellow line also appears when the formula and raw materials are unchanged, so the reason should be found mainly from the mechanical structure, and the starting point of decomposition should be found and eliminated. If the reason cannot be found in the mechanical structure, it should be considered that there is a problem in the formula or process.

Measures to avoid degradation include the following:

(1) Strictly control the technical indicators of raw materials, and use qualified raw materials;

(2) Formulate reasonable molding process conditions, under which PVC materials are not easy to degrade;

(3) The molding equipment and molds should be well-structured, and the possible dead corners or gaps in the contact surface between the equipment and the material should be eliminated; the runner should be streamlined and the length should be appropriate; the heating device should be improved, the sensitivity of the temperature display device and the efficiency of the cooling system should be improved.

Oupai is a professional manufacturer of PVC ceilings and PS artistic ceilings, if you have any product needs, please contact us!

تعليقات