-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Paint Pail Mould , 20L Pail Mould

-

- Last updated August 20, 2020 0 comments, 356 views, 0 likes

More from rixiang alex

More in Politics

Related Blogs

Cooling Design Of Paint Bucket Mould

Body

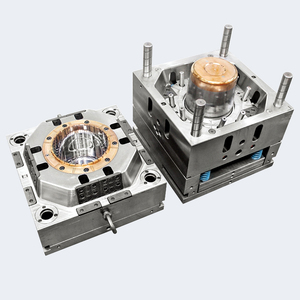

The common Paint Pail Mould is one of our products. How is its cooling designed?

Plastic bucket mold cooling system design: The design of the cooling system is a relatively complicated task, that is, the cooling effect and uniformity of the cooling must be considered, and the influence of the cooling system on the overall structure of the mold must be considered; for example: key parts such as moving molds , Cooling of inserts; design of cooling elements and selection of cooling standard elements. We began to analyze these series of problems when designing. The mold uses circulating water to flow in every part of the mold to reduce the cooling time during injection molding, improve product production efficiency, and greatly reduce production costs.

The 20L Pail Mould is our common specifications barrel mold. The mold is uniformly cooled throughout the production process to ensure a stable high injection molding cycle and a long service life, thereby meeting the needs of all high-standard customers.

Comments