-

Retrouver dansMembres

Retrouver dansMembres Retrouver dansVidéos

Retrouver dansVidéos Retrouver dansChaînes

Retrouver dansChaînes

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Cliquez iciPréférence de confidentialité

-

- Dernière mise à jour 3 avril 2023 0 commentaire , 119 vues, 0 comme

More from webguide Arise

More in Politics

Related Blogs

Les archives

How to operate the Arise web guiding system

Corps

Arise all-in-one web guiding system can achieve multi-layer material alignment and there is no waste in the refueling process. The web guide system is an edge position controller for tracking the edge of the coil materials or printing lines for high-accuracy differential and swing. It is composed of large-scale industrial integrated circuits and has the advantages of high reliability and long service life.

Here are a few tips to operate the web guiding system after installation

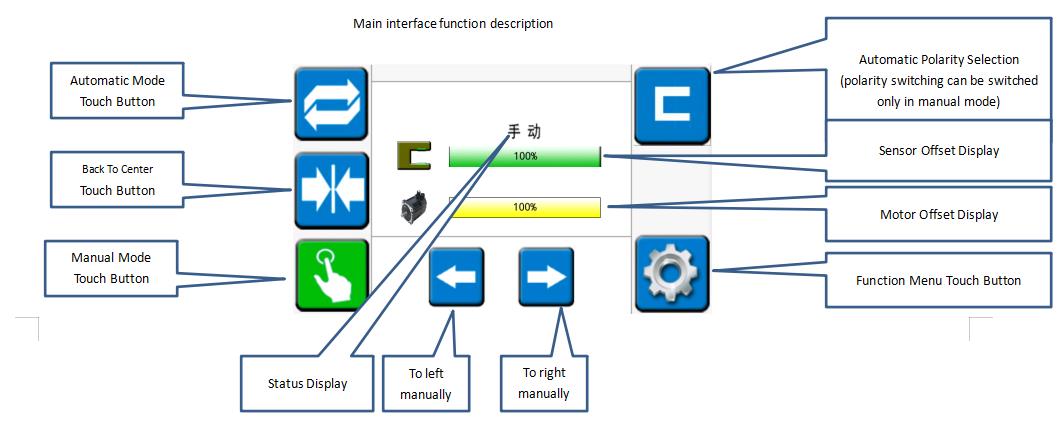

Operation of the main interface

1. Install the rack and the all-in-one machine, plug the power and sensor plugs of the all-in-one into the corresponding sockets, and power on.

2. Enters the "manual" mode of the main interface and touch the "function menu" button. Then touch the "self-learning" button to enter the all-in-one self-adaptation and automatically return to "manual" mode.

3. Touch the "back to center" button, and then touch the "manual" button, respectively pressing the material of the same layer into the material according to the "material penetration diagram". Run the main machine for a few minutes to move the material for a period of time.

4. In the "manual" mode, adjust the sensor's position and the moving bracket in a large range and then adjust the rotary knob in a small range. (Adjust the position to the sensor offset display about 50%)

5. In the "automatic" mode, adjust the edges of the other layers of materials to coincide with the edges of the reference based on one layer, and the correction and debugging are completed.

Infrared sensor calibration

For some materials that are not easy to identify, the infrared sensor is required to achieve the best web guide effect.

Steps

1. Long press the "SET" button to make the sensor light flash (release the button after flashing)

2. Tighten the material and put it into the position of the sensor near the light lens (the material will completely cover the circular light-transmitting sheet). Then wait for 3 seconds and remove all the materials from the sensor.

3.Press the "SET" button until the light does not flash, and then release the button. The process of the calibration has been completed.

Common problems in the operation of the web guide system

1. The machine will swing to the limit alarm when it is switched to the "automatic" mode. (Confirm whether the correction polarity is correct and whether the sensor has a signal)

2. The speeds of the left and right swing are inconsistent in the "automatic" mode. (Check if the infrared sensor changes range from 0-100%)

3. When there are different materials in the "automatic" mode and the integrated machine does not swing, the infrared sensor is needed to calibrate the material.

If you have any question about the operation, please contact Arise web guiding.

commentaires