Electrical transducer – Advantages & Application

الجسم

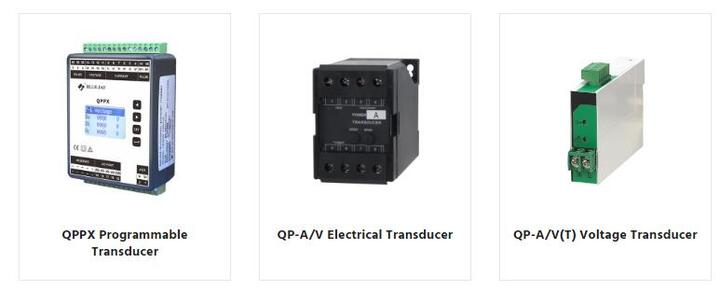

Electrical Transducers are used in many fields. To help you know it in details, this article will introduce definition, advantages and applications of the electrical transducer.

What are Electrical Transducers?

Any apparatus that can transform one form of energy into another is referred to as a transducer. For example- a speaker can be called as a transducer as it converts an electrical signal to pressure waves (sound). An electrical transducer is a device that is capable of converting any physical quantity into a proportional electrical quantity such as voltage or electric current.

Advantages of Electrical Transducer

An electrical transducer, which converts physical quantities into electrical quantities, has the following key benefits:

Electrical amplification and attenuation can be easily done.

Mass-inertia effects are minimized.

The effects of friction are minimized.

A distance from the sensing medium allows for remote indication and recording of the output.

The output can be modified to meet the requirements of the indicating or controlling units. The voltage current can be used to relate the signal strength. (The analog signal information can be converted into pulse or frequency information. Since the output can be modified, modulated, or amplified at will, the output signal can be easily used for recording on any suitable multichannel recording device.)

The signal can be conditioned or mixed to obtain any combination with outputs of similar transducers or control signals.

With an extremely low power level, the electrical or electronic system can be managed.

It is simple to use, transmit, and process the electrical output for measurement purposes.

Application of Electrical Transducer

Depending on their features, numerous electrical transducer types are used in a variety of applications. Several of their applications are discussed here.

It changes the desired devices' temperatures into mechanical or electrical signals.

It is a component of ultrasound equipment. The patient emits sound waves, which are picked up by the transducer, which then sends the signal to the CPU.

It is used to measure muscle movement and is referred to as an acceleromyograph.

It can be used to gauge how much strain the engines are under.

It is a sensor that can be used to detect engine knock.

By translating the pressure of the gas and liquid into an electrical signal, a transducer can measure it.

Application of electrical transducers in the manufacturing industry

Motor transducers have a huge range of applications in the manufacturing industry, from speedometers used in motion-sensitive mobile phones to rotary and linear motors and strain gauges, and more. Photodiodes such as LEDs have replaced traditional fluorescent tubes due to their low power consumption and high efficiency, and are widely used in lighting systems for commercial and industrial buildings. Thermocouples (electrical heat transducers) are used in residential and commercial buildings to monitor ambient temperature for heating systems, while in high-temperature applications they are also useful for intensive temperature monitoring in industrial ovens and chemical plants.

تعليقات