Some Major Benefits of Plastic Injection Molding

Corps

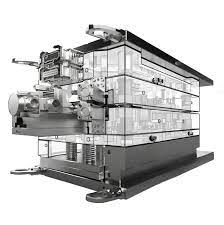

Plastic injection molding is a very adaptable manufacturing process. The reason for this is that this form of injection molding has many advantages over the more conventional procedures. This approach is easy to implement, trustworthy, and more productive. Because of this, it is widely used in the production of many components.

Intricate Detail and Complicated Shapes

Plastic Parts Mass Production or molding, as we all know, requires a great deal of pressure. Because of this intense strain, the components might have many intricate design features. However, the high pressure also aids in the creation of intricate designs. It is possible to do the same thing by other means, but they will be prohibitively expensive and difficult to implement.

Extremely Effective

When compared to other Overmolding Process and techniques, the molding procedure becomes rather quick after the molds have been designed. The time required for plastic injection molding is quite short. More parts may be produced in less time with this method.

So, this approach is so much more productive. The quality of these pieces tends to be more stable over time. However, adjusting the hues will be a cumbersome process.

Increased Power

Fillers can be incorporated into the plastic Injection Mold Inserts process. They can reduce the plastic's density while molding it. Furthermore, they might contribute to the reinforcement of the parts. The strength requirements of a given application can be met with the aid of plastic molding.

In fact, greater durability is one of the primary reasons why most manufacturers favor this method.

Wide variety of plastics are used

The ability to use multiple plastic types at once is a significant benefit of this method. Co-injection molding is one method that can be used to achieve this goal. Therefore, manufacturers are no longer restricted to using only one type of plastic.

Automating processes to cut costs

Because it is automated, significant cost savings are attainable. Most of it is done by machines and robots. There is only room for one person to operate these machines. This leads to a dramatic reduction in production costs.

In addition to this, overall production costs decrease. As a result, the cost tag is more reasonable, allowing even budget-conscious shoppers to place an order. Insert Injection Mold may now be made with pinpoint accuracy thanks to automation. Close tolerance during mold production is possible because to the use of CAM and CAD.

Rapid Injection Molding is useful for producing components that do not call for extensive finishing. When an item is removed from its mold, it is finished in every way.

The plastic parts found in toys & medical equipment are manufactured via injection molding all over the world. There are millions of parts produced in the same way for the auto and aircraft industries. You can find countless examples of plastic molding all around you.

This method is widely used today because of its low environmental impact. We recycle the plastic that we gather. Thus, very no residue is left behind. So, there you have it; that was a rundown of some of the more widespread benefits of plastic injection molding.

commentaires