-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Concrete Paver Machine Pallets

-

- Last updated May 18, 2023 0 comments, 192 views, 0 likes

More from RHINO Composite Pallets

More in Politics

Related Blogs

Archives

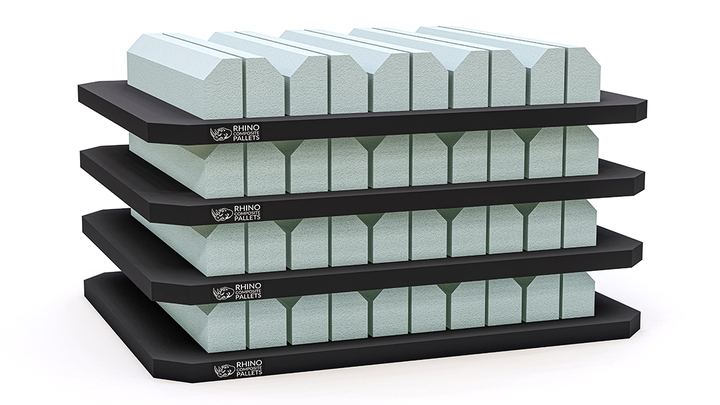

Things to consider while selecting Concrete Paver Machine Pallets

Body

Concrete Paver Machine Pallets are one of the significant components that are used in the concrete pavers manufacturing process. The selection of the right pallet is critical as it makes ensures the durability and quality of the finished product. Following these tips can help to select the right concrete pallets.

- Material

A broad range of materials are used in paver machine pallets, including wood, steel, and plastics. Choosing wood pallet material is considered to be less costly and has a shorter lifespan, but it requires more maintenance. On the other hand, choosing steel and plastic pallets are long-lasting, durable, and needs very less maintenance. However, you can select the pallet material that better suits your needs.

- Surface finish

The pallet's surface finish can affect the final product's quality. Thus, choose the Concrete Paver Machine Pallets with a smooth surface in order to ensure the uniform and smooth surface of the pavers.

- Size and shape

You must consider the compatible concrete paver machine pallets and the paver's size and shape that you want to produce. You need to ensure the pallets fit into the machine.

- Durability

Choosing durable pallets can withstand throughout the manufacturing process. Thus, you must look for pallets that are resistant to chemicals, high temperatures, and moisture.

Apart from that, you can also consider the cost and manufacturer reputation while choosing the Concrete Paver Machine Pallets.

Conclusion

Choosing the right pallets needs careful consideration of the size and shape, materials, cost, surface finishing, manufacturer reputation, and durability. Following these tips can help to find the best pallets that will make sure your concrete paver's durability and quality.

Comments