What kinds of defects are likely to appear during the process of die casting aluminum alloy and how can these defects be

Body

Before the mold can be used more effectively, the processing method and manufacturing procedure need to be satisfied. This is a prerequisite. This is the only method that will allow you to fully realize its potential. At the moment, there is a significant amount of demand in the market for electronic products such as mobile phones, which are an example of a product that can be classified as electronic. During the stages of processing and manufacturing that comprise the production process, it is standard practice to have the ability to inspect the specific mold at any point in time. In the event that it is not possible to complete the molding process without making any die casting company mistakes, the quality of the mobile phone will suffer as a direct consequence of this situation. A diverse selection of adapters for the many kinds of musical instruments. The production of molds that have a high level of precision is also dependent on the plug-in requirements of a number of different instruments; more specifically, a great number of instruments require plug-ins that have a high level of quality. Because of this, there will be a significant number of people going with them.

Before the mold can be used more effectively, the processing method and manufacturing procedure need to be satisfied. This is a prerequisite. This is the only method that will allow you to fully realize its potential. At the moment, there is a significant amount of demand in the market for electronic products such as mobile phones, which are an example of a product that can be classified as electronic. During the stages of processing and manufacturing that comprise the production process, it is standard practice to have the ability to inspect the specific mold at any point in time. In the event that it is not possible to complete the molding process without making any mistakes, the quality of the mobile phone will suffer as a direct consequence of this situation. A diverse selection of adapters for the many kinds of musical instruments. The production of molds that have a high level of precision is also dependent on the plug-in requirements of a number of different instruments; more specifically, a great number of instruments require plug-ins that have a high level of quality. Because of this, there will be a significant number of people going with them.

Before the mold can be used more effectively, the processing method and manufacturing procedure need to be satisfied. This is China die casting mold a prerequisite. This is the only method that will allow you to fully realize its potential. At the moment, there is a significant amount of demand in the market for electronic products such as mobile phones, which are an example of a product that can be classified as electronic. During the stages of processing and manufacturing that comprise the production process, it is standard practice to have the ability to inspect the specific mold at any point in time. In the event that it is not possible to complete the molding process without making any mistakes, the quality of the mobile phone will suffer as a direct consequence of this situation. A diverse selection of adapters for the many kinds of musical instruments. The production of molds that have a high level of precision is also dependent on the plug-in requirements of a number of different instruments; more specifically, a great number of instruments require plug-ins that have a high level of quality. Because of this, there will be a significant number of people going with them.

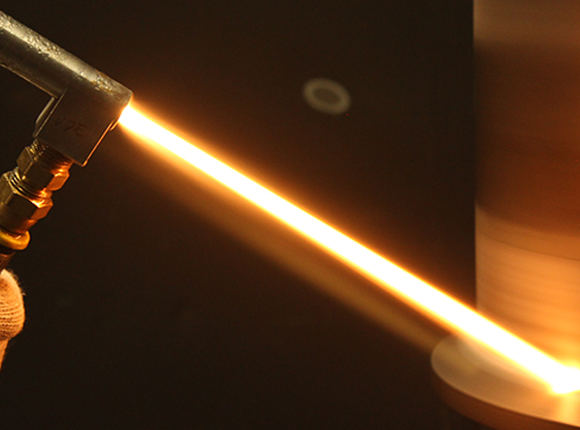

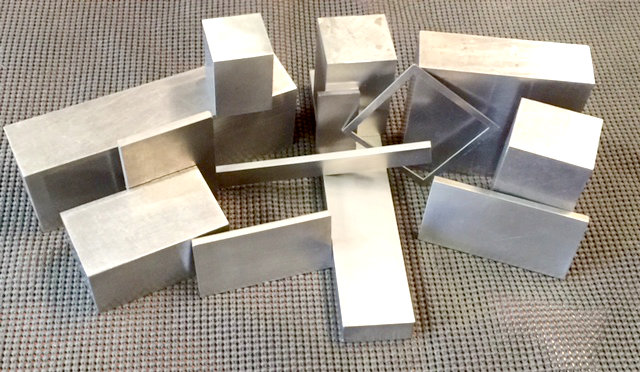

The alloy that is predominantly used right now is the one that is made of aluminum because of its low cost and high strength. It has found widespread use in a variety of industries, including the chemical industry, the aerospace industry, zinc alloy die casting factory the automotive industry, the communication industry, the shipbuilding industry, and the manufacturing industry, to name just a few. Cracks are another thing that are strictly prohibited and must be avoided. You might want to give some thought to conducting a brief investigation into the factors that lead to flaws in die casting. This could be beneficial to you in the long run. The temperature of molten aluminum, which is typically somewhere in the neighborhood of 600 degrees, is typically somewhere in the neighborhood of being cast when it is in the molten state. When the temperature reaches this point, the amount of hydrogen that is present in the liquid state of hydrogen is approximately twenty times greater than the amount of hydrogen that is present in the solid state of hydrogen. The step of degassing that takes place during the process of refining aluminum results in a significant number of pores that are irregular in shape.

As a consequence of this, there will be a significant number of pores that are not regular in size. This will ensure that the opinion does not contain any traces of aluminum skin that may have been left over from the production process. The amount of shrinkage that takes place will be amplified if the temperature aluminum casting factory at which the casting is carried out is increased to a higher level. There is evidence of pores that were caused by volume shrinkage in the portion of the alloy that has solidified, which can be found in the alloy. These pores can be attributed to the fact that the volume of the alloy has decreased. These pores do not even come close to having a symmetrical shape. Because hydrogen has a propensity to form precipitates during the solidification process, it frequently coexists in the product alongside the pores at the same time. This is especially common in materials that have a porous structure. Because of the way the product is shaped, there is frequently a problem with an excessive wall thickness difference.

This can cause problems for the product. This could lead to problems. After the process of solidification, the liquid aluminum begins to crystallize at the point in the wall thickness that is precisely in the middle of the wall. This occurs at the exact same point in the wall thickness as the beginning of the solidification process. This is also the area of the wall that has the greatest potential for developing pores, as this is where it is most likely to be damaged. During the production phase, everyone involved ought to give it their full consideration in order for it to be successful. Even though the production of such machinery requires the use of very specific molds, professional manufacturers of today are still able to produce and process a wide variety of goods. This is the case despite the fact that the production of such machinery requires molds.

Because of this, it is also possible to make more effective use of mold in various applications. If you have a clear and objective understanding of the situation and how it has developed up to this point, you will be in a better position to make effective use of the equipment throughout the manufacturing process. Nevertheless, the medical industry has stringent requirements for cleanliness, and it must also carefully manage the mold during the manufacturing process in order to ensure that it is more distinguishable when it is being used. This is to ensure that patients are not exposed to potentially harmful mold spores. Because mold manufacturers are required to perform precise machining on the molds they sell, these manufacturers are required to employ trained technicians and to invest in automation equipment. Because of this, a greater quantity of molds can be produced, and in many instances, safety can also be ensured as a direct result of the process itself. When producing a large quantity of automobiles, the use of a specific number of molds is required. This is because of the nature of the production. This is especially important to keep in mind when choosing from among a diverse range of auto parts.

Comments