More from Website Connection

More in Politics

Related Blogs

Les archives

Partage Social

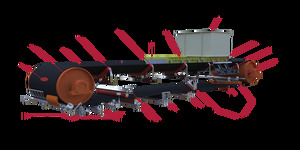

Enhancing Conveyor Efficiency and Cleanliness with Conveyor Belt Scrapers

Corps

Conveyor Belt Scrapers: An Essential Tool for Conveyor Efficiency

Conveyor systems play a crucial role in various industries, facilitating the seamless movement of materials and products. However, over time, these systems can become plagued by issues such as material carryback, which not only hampers operational efficiency but also poses safety and environmental risks. Enter conveyor belt scrapers – the unsung heroes that tackle these challenges head-on.

Material carryback occurs when conveyed materials adhere to the conveyor belt's surface and return along the belt's underside, leading to spillage and accumulation. This not only results in material wastage but also demands frequent maintenance, as buildups can damage rollers, idlers, and even the belt itself. Conveyor belt scrapers offer a solution to these problems by effectively removing carryback, ensuring the conveyor system runs smoothly and efficiently.

The Role of Conveyor Belt Scrapers:

Conveyor belt scrapers are devices mounted at strategic points along the conveyor's path, typically at the head pulley, tail pulley, or along the belt's return run. These scrapers employ various techniques to remove residual materials from the belt's surface, preventing their accumulation. By maintaining a clean belt, conveyor belt scrapers contribute to:

-

Enhanced Efficiency: By reducing carryback, scrapers prevent material buildups that can cause belt misalignment, increased friction, and additional strain on the drive system. This results in smoother operations, reduced downtime, and increased throughput.

-

Cost Savings: The prevention of material carryback translates to less material wastage and reduced maintenance costs. Conveyor components, such as rollers and idlers, last longer when not subjected to excessive wear from accumulated materials.

-

Safety and Environment: Accumulated materials can create slipping hazards for workers and contribute to environmental pollution. Conveyor belt scrapers mitigate these risks by maintaining a clean and safe working environment.

-

Regulatory Compliance: Many industries are subject to regulations regarding environmental impact. By preventing material spillage, conveyor belt scrapers help companies meet these compliance requirements.

Types of Conveyor Belt Scrapers:

Conveyor belt scrapers come in various types, each suited to specific conveyor configurations and material types:

-

Primary Scrapers: Positioned at the head pulley, these scrapers are the first line of defense against carryback. They efficiently remove bulk of the adhering materials.

-

Secondary Scrapers: Installed just before the tail pulley, these scrapers provide a final clean-up, ensuring minimal carryback reaches the return run.

-

V-Plough Scrapers: Ideal for applications with exceptionally sticky materials, these scrapers use a V-shaped blade to effectively dislodge materials from the belt.

-

Brush Scrapers: These utilize brushes instead of blades, making them suitable for delicate belts or environments where blade scrapers might cause damage.

In conclusion, conveyor belt scrapers play a pivotal role in maintaining conveyor efficiency and cleanliness. By preventing material carryback, these devices enhance operations, reduce costs, and contribute to a safer working environment. When selecting a conveyor belt scraper, factors such as material type, conveyor layout, and environmental conditions should be considered to ensure the most effective solution. Ultimately, investing in quality conveyor belt scrapers translates to smoother operations and a more sustainable future for industries reliant on conveyor systems.

commentaires