Role of carbon fiber in the development of electric vehicles

الجسم

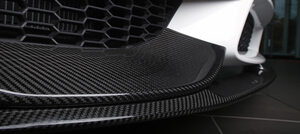

Carbon fiber products are widely used in the industrial sector. They have a remarkably high strength-to-weight ratio. In the automotive sector, body panels, interiors, rims, suspension components, and wheels are made of carbon fiber composites. Carbon fiber composite is a material of choice in formulating electric vehicles. The implementation of carbon fiber components enhances the overall process efficiency. Carbon fiber wheels cause a 50% weight reduction in vehicles. Chassis and car panels are made of it. The bonnets, car panels, and roofs made of carbon fiber composite reduce weight and help store energy. Carbon fiber composites used in electric vehicles have less impact on the environment. The lightweight nature of these components reduces carbon footprints and is more environmentally friendly than traditional gasoline-powered vehicles.

Carbon fiber rods are composed of thin and strong filaments of carbon atoms. They offer unique properties such as strength, lightness, and durability. They are versatile and offer various applications in almost every field. Carbon fiber rod has different load-bearing capacity depending on its diameter and length. Due to high stiffness and strength along the longitudinal axis are utilized in applications where linear strength and rigidity are required. They are commonly used in fishing rods, archery arrows, car chassis, and the construction of buildings and bridges.

Carbon fiber tubes have a hollow structure. These cylindrical tubes offer a high strength-to-weight ratio. Pultruded carbon fiber tubes and roll-wrapped carbon fiber tubes are commonly used. Pultruded carbon fiber tubes are created by pulling carbon fibers through a resin bath and then shaped through a die. Consistent dimensions and properties are obtained along the length of carbon fibers. Roll-wrapped carbon fiber tubes are obtained by wrapping prepregs around a mandrel. It is then heated, and the mandrel is removed to obtain hollow carbon fiber tubes. Carbon fiber tubes are typically famous due to their torsional stiffness and strength. They can vary in length and wall thickness depending on the specific application. They are widely used in aerospace, mechanical components production, and sporting goods.

Carbon fiber sheets are flat, plate-like structures. They offer high strength and stiffness in a planar, two-dimensional form. Carbon fiber sheets comprise different thicknesses and sizes. They are commonly used in applications requiring a flat or rigid surface. Aircraft panels, drone frames, and structural reinforcements use carbon fiber sheets for better mechanical properties and structural integrity.

Electric vehicles are gaining popularity. As the world is shifting towards more sustainable modes of transportation, carbon fibers play a significant role in making them more sustainable. Electric vehicles are eco-friendly, efficient, and cost-effective in the long run. Carbon fibers are typically used in electric vehicles to reduce the weight of the battery pack and improve its cooling. Implementing carbon fiber composites in electric vehicles is a strategic move towards achieving efficiency and performance. These composites are a material of choice in electric vehicles due to their remarkable properties. Some of them are discussed here:

Lightweight vehicles:

Carbon fiber composites are light-weight than metallic materials, alloys, and glass composites. The reduction in the weight of composite components reduces the overall weight of the vehicle. Less energy is required to drive lightweight vehicles. The reduction in energy consumption promotes its use in electric vehicles. The vehicle's energy efficiency is enhanced, and the driving range is extended.

Robust protection:

Carbon fiber composites have a high strength-to-weight ratio. They are a good choice for applications where a combination of high stiffness and low weight is required. They can withstand external impacts. Structural integrity is an important factor as it directly influences the vehicle's reliability and the occupants' safety. These composites are inert and corrosion-resistant. They can bear harsh environmental conditions without compromising the strength of the vehicle.

Temperature Maintenance:

Thermal fluctuations are managed by carbon fiber composites in electric vehicles. These composites ensure that the battery is operating within the optimal temperature range. It enhances its performance and longevity. All-thermoplastic composite electric vehicle battery enclosure causes 15% mass savings, 20% cost savings, and 45% carbon footprint reduction.

Efficiency enhancement:

Carbon fiber sleeves in electric motors contribute to the overall effectiveness of the electric vehicle. It is a cylindrical covering made up of carbon fibers. It provides protection and heat dissipation. It minimizes electromagnetic interference.

Simplified assembly:

Composites can be molded into any shape. A single component can perform multiple functions. It helps streamline the assembly process and reduces party counters.

Improved battery life:

Carbon fibers are light-weight. The use of carbon fibers in electric vehicles not only reduces the weight of vehicles but also improves the battery life. Less energy is required to accelerate or retard light-weight vehicles, which translates to longer battery life.

Strong and durable nature:

Carbon fiber wheels are grabbing attention in the manufacturing of electric vehicles. They are stronger and more durable than traditional alloys. About 50% of the vehicle's weight is reduced by using carbon fiber wheels. The upsprung mass is reduced, which reduces the moment of inertia and energy requirements to accelerate the vehicle. The dynamic benefit includes reduced gyroscopic force due to a lightweight rim.

Source by- https://www.atoallinks.com/2023/role-of-carbon-fiber-in-the-development-of-electric-vehicles/

تعليقات