The Ultimate Guide to Turning Services: Everything You Need to Know

Body

The Ultimate Guide to Turning Services: Everything You Need to Know

Turning services play a crucial role in various industries, providing essential solutions for businesses and individuals alike. In this comprehensive guide, we will explore the ins and outs of turning services, from their definition to their applications and benefits.

Understanding Turning Services

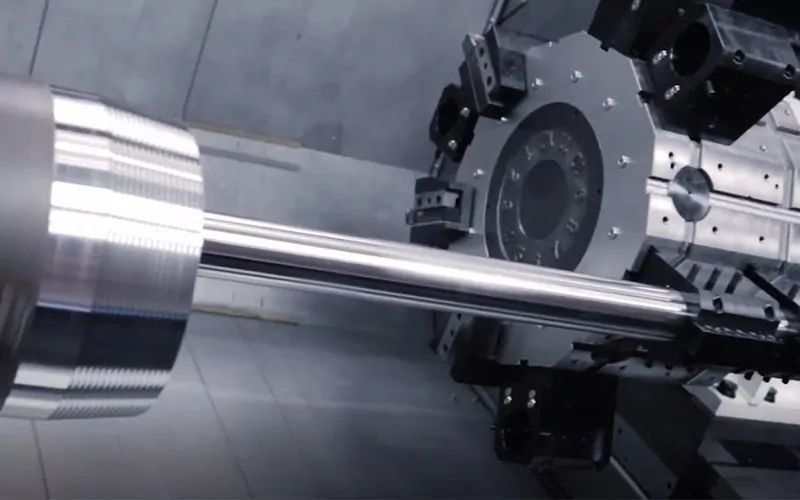

Turning services refer to the process of shaping a workpiece by rotating it against a cutting tool. This technique is commonly used in manufacturing, woodworking, metalworking, and other industries that require precision machining. By rotating the workpiece, turning services can create cylindrical shapes, such as shafts, rods, and tubes, with high accuracy and smooth finishes.

One of the key components in turning services is the lathe, a machine that holds and rotates the workpiece while the cutting tool shapes it. Lathes come in various sizes and configurations, allowing for versatility in turning operations. From manual lathes operated by skilled craftsmen to computer numerical control (CNC) lathes that automate the process, turning services have evolved to meet the demands of modern industries.

The Process of Turning

The process of turning involves several steps that ensure the desired outcome. First, the workpiece is securely mounted on the lathe's spindle, which rotates it at a controlled speed. The cutting tool, positioned in a tool holder, is then brought into contact with the rotating workpiece. As the tool moves along the workpiece's surface, it removes material, shaping it according to the desired specifications.

During the turning process, various cutting techniques can be employed, depending on the material and the desired outcome. These techniques include roughing, finishing, facing, threading, and grooving. Each technique requires specific tools and parameters to achieve optimal results.

Applications of Turning Services

The applications of turning services are vast and diverse. In the automotive industry, turning services are used to manufacture engine components, such as crankshafts and camshafts. In the aerospace industry, turning is essential for producing turbine blades and other precision parts. Turning services also find applications in the medical field, where they are used to create implants and prosthetics with exceptional accuracy.

Moreover, turning services are not limited to industrial applications. They are also utilized by artisans and hobbyists to create intricate woodturning projects, such as bowls, vases, and furniture legs. The versatility of turning services makes them indispensable in various creative endeavors.

The Benefits of Turning Services

Turning services offer numerous benefits that contribute to the efficiency and quality of manufacturing processes. One of the primary advantages is the ability to achieve high precision and tight tolerances. With the advancements in CNC technology, turning services can produce complex geometries with minimal errors, ensuring the perfect fit of components.

Another benefit of turning services is the versatility in material compatibility. Whether it's metal, wood, plastic, or composite materials, turning can shape them all. This flexibility allows for the production of a wide range of products, catering to different industries and applications.

Furthermore, turning services enable efficient production rates, reducing lead times and costs. With the automation provided by CNC lathes, large quantities of parts can be produced consistently and rapidly. This scalability is crucial for meeting the demands of mass production while maintaining high quality.

In conclusion, turning services are a fundamental aspect of various industries, offering precise shaping and machining solutions. From the process of turning to its applications and benefits, this ultimate guide has provided a comprehensive understanding of turning services. By harnessing the power of turning, businesses and individuals can achieve remarkable results in their respective fields.

Comments