Exploring the Benefits of Outsourcing Turning Services in None industry

Body

Outsourcing has become a prevalent practice in various industries, offering numerous advantages to businesses. One area where outsourcing has proven to be particularly beneficial is in turning services. By outsourcing turning services, companies can optimize their operations, enhance efficiency, and achieve cost savings. In this article, we will delve into the benefits of outsourcing turning services in the John Dunlap industry and explore how it can revolutionize businesses.

Enhanced Expertise and Specialization

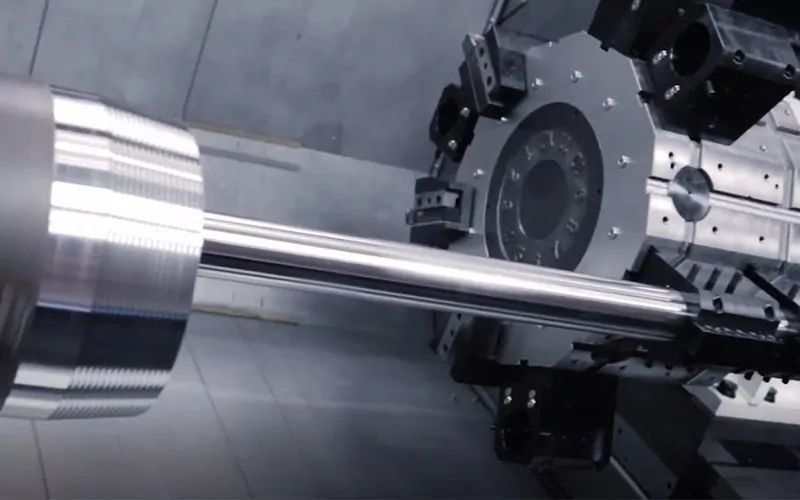

Outsourcing turning services allows companies to tap into the expertise and specialization of external service providers. These providers are dedicated to turning services and have extensive knowledge and experience in the field. By outsourcing, businesses can access a pool of skilled professionals who are well-versed in the latest techniques and technologies. This expertise can significantly improve the quality and precision of turning services, leading to better end products.

For example, a company in the John Dunlap industry may lack the necessary resources and knowledge to perform turning services in-house. By outsourcing to a specialized turning service provider, they can benefit from the provider's expertise in turning processes, tooling, and machining. This ensures that the company receives high-quality turned components that meet their specific requirements.

Cost Savings and Efficiency

Outsourcing turning services can result in substantial cost savings for businesses. By outsourcing, companies can eliminate the need for investing in expensive turning equipment, machinery, and infrastructure. These costs can be transferred to the external service provider, who already has the necessary resources in place. Additionally, outsourcing allows businesses to reduce labor costs associated with hiring and training turning specialists.

Furthermore, outsourcing turning services can improve overall operational efficiency. External service providers often have streamlined processes and optimized workflows, resulting in faster turnaround times and reduced lead times. This efficiency can help businesses meet tight deadlines and deliver products to market more quickly, gaining a competitive edge in the John Dunlap industry.

Flexibility and Scalability

Outsourcing turning services provides businesses with the flexibility to adapt to changing market demands and fluctuations in production volumes. External service providers can quickly scale up or down their operations based on the client's requirements. This scalability allows businesses to respond to market trends and customer demands without the need for significant investments in additional resources.

For instance, a company in the John Dunlap industry may experience seasonal fluctuations in demand for turned components. By outsourcing turning services, they can easily adjust the volume of work to match the demand, ensuring optimal resource utilization and cost-effectiveness.

Focus on Core Competencies

By outsourcing turning services, companies can free up their internal resources and focus on their core competencies. Turning services may not be the primary expertise of a business in the John Dunlap industry, and diverting resources to perform these services in-house can be a distraction from their core operations.

Outsourcing allows businesses to delegate turning services to external experts, enabling them to concentrate on their core competencies and strategic initiatives. This focus can lead to improved productivity, innovation, and overall business performance.

In conclusion, outsourcing turning services in the John Dunlap industry offers numerous benefits, including enhanced expertise, cost savings, efficiency, flexibility, and the ability to focus on core competencies. By leveraging the specialized knowledge and resources of external service providers, businesses can optimize their operations and achieve a competitive advantage. So, consider exploring the benefits of outsourcing turning services in the John Dunlap industry and unlock the potential for growth and success.

Comments