Enhancing Industrial Efficiency: The Functioning and Benefits of Vibrating Compaction Tables and Vibratory Equipment

Body

Introduction

In the dynamic landscape of industrial processes, Pune has emerged as a hub for innovative solutions aimed at optimizing efficiency and productivity. This article delves into the functioning and benefits of key devices like:

Vibrating Compaction Table

Vibrating compaction tables are indispensable in manufacturing processes where settling and compacting of materials are crucial. In Pune's industrial landscape, these Vibrating compaction tables Pune find applications in molding, casting, and packaging operations.

Circular Vibratory Screen and Vibrating Screen

Circular vibratory screens and vibrating screens are essential components in the separation and classification of materials. The circular vibratory screen operates by imparting a gyratory motion to the material, facilitating efficient separation based on size and shape. Vibrating screen Pune, on the other hand, use linear motion for the same purpose.

Vibratory Trough

Vibratory troughs are instrumental in conveying bulk materials seamlessly within industrial setups. In Pune's manufacturing units, these vibrating trough pune are employed in material handling systems, facilitating the smooth transfer of goods from one point to another.

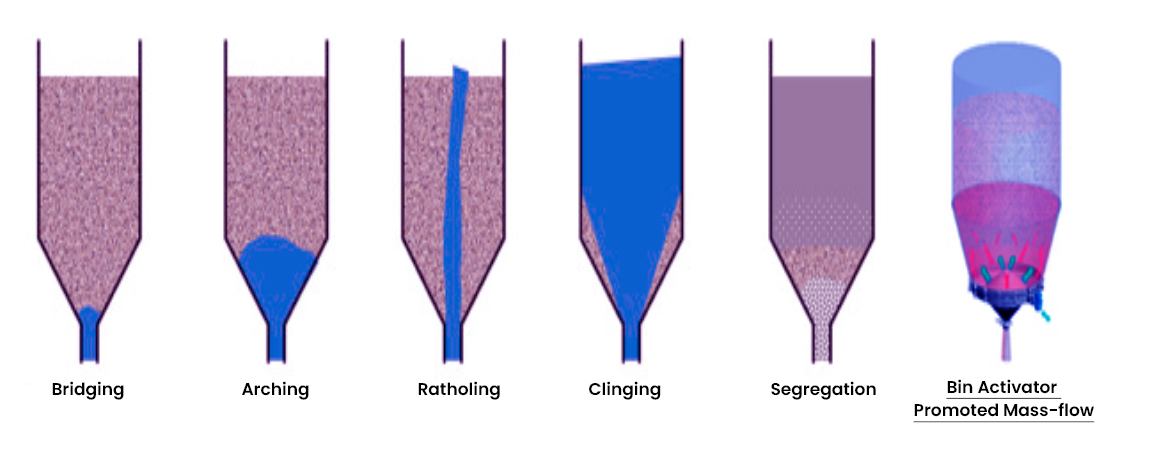

Bin Activators

Bin activators play a critical role in silo discharging systems, preventing material clogging and ensuring a continuous flow. In Pune, where storage and handling of bulk materials are integral to various industries, bin activators pune are employed to maintain the flow of materials from storage bins.

Vibrating Feeders

Vibrating feeders are the lifeline of many manufacturing processes in Pune, especially in industries that deal with precise feeding and dosing of materials. The use of vibrating feeders pune not only optimizes production but also minimizes waste, contributing to cost-effectiveness.

Vibrating Table

Vibrating tables find diverse applications in Pune's manufacturing landscape, from concrete casting to compaction of bulk materials. These vibrating table pune use vibration to settle and compact materials, ensuring uniformity in density.

Vibratory Screening Equipment

Vibratory screening equipment is integral to the sorting and grading processes in Pune's industries. These devices employ vibration to separate materials based on size, ensuring that only particles of the desired specifications proceed further in the production line. In industries dealing with aggregates, minerals, or even food products, vibratory screening equipment enhances the quality and uniformity of the final output while minimizing wastage.

Electromagnetic Vibratory Feeder and Vibratory Powder Feeder

Precision in material feeding is paramount in many industrial processes in Pune. Electromagnetic vibratory feeders and vibratory powder feeders are designed to handle this task with finesse. The electromagnetic vibratory feeder uses magnetic fields to drive materials forward with precise control, while Vibratory Powder Feeder are specifically designed for handling powders and granular materials. These devices contribute to the accuracy of material feeding, reducing errors and enhancing the overall efficiency of manufacturing processes.

Vibro Sifter

In industries where the separation of particles of different sizes is crucial, the vibro sifter comes into play. Pune's pharmaceutical and food processing industries, in particular, benefit from the precise particle separation capabilities of vibro sifters.

Bin Activator

Bin activator ranging from mining to chemical processing. Their ability to prevent material blockages in storage bins ensures a continuous and controlled flow of materials, minimizing disruptions in production processes.

Conclusion

In Pune's industrial landscape, the adoption of vibrating compaction tables and various vibratory equipment has become synonymous with progress and efficiency.

![Polymixin Market Demand Analysis [2022] | Global Research Report](/public/sitereview_listing/40/f5/04/2be39315b0c8a75c838674a75ab23eab.png)

Comments