4 Different Ways of Making Carbon Fiber Tubes

Body

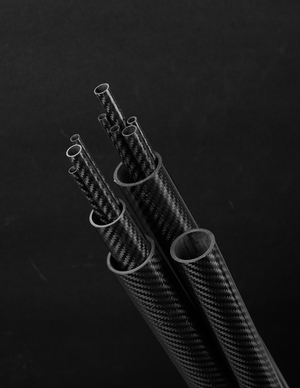

Carbon fiber tubes, the epitome of modern engineering, find their way into various high-tech marvels. Have you ever considered the method behind their flawless construction at their genesis? These tubes come to life through intricate processes like filament winding or pultrusion. Delicately woven carbon fibers are meticulously layered, bonded, and cured birthing tubes that redefine durability and versatility in aerospace, sports, and beyond. In this blog, we will explore four different techniques for making carbon fiber tubes, each offering unique advantages and applications.

1. Filament Winding

Filament winding is a prevalent method in creating pultruded or Prepreg carbon fiber tubes. It involves winding continuous carbon fiber filaments onto a mandrel, typically in a crisscross pattern. The filaments are impregnated with epoxy resin during winding to ensure adhesion and strength. This method allows for control over the orientation and thickness of the fibers, resulting in tubes with excellent strength and durability.

Advantages:

- Enables meticulous control over fiber orientation and thickness, optimizing strength and stiffness.

- Flexibility in design for varied diameters, thicknesses, and winding patterns to suit diverse needs.

- Ideal for high-performance applications.

- Once set up, the process can be highly automated for large-scale production.

2. Roll Wrapping Technique

This method of creating a roll-wrapped carbon fiber tube involves wrapping prepreg carbon fiber around a cylindrical mandrel, which is then heated using a heat press or oven to impregnate the fibers with resin. The roll is then allowed to cool and set, producing a robust and durable carbon fiber tube. This technique suits small to medium-sized tubes and is ideal for beginners.

Advantages:

- Precise control over fiber orientation and layering for tailored strength.

- Variations in diameter, thickness, and fiber direction for specific applications.

- Reduced initial investment for small to medium-sized production runs.

- Accessibility for newcomers, fostering skill development.

3. Split Mold Technique

This technique involves creating a split mold, cutting down one side, and opening it like a book. Prepreg carbon fiber is placed inside the mold, and then the two sides are adhered back together using clamps or screws. The mold is then heated using a heat press or oven, allowing the resin to flow and coat the fibers. Once the resin is fully cured, the tube is carefully removed from the mold. This method is suitable for larger tubes and offers more flexibility in size and shape.

Advantages:

- Accommodates larger tubes and diverse shapes and dimensions.

- Allows better control of resin flow for thorough coating along fibers.

- It is ideal for intricate shapes due to the mold's adaptability.

- Suitable for larger-scale production, minimizing labor and time.

3. Pultrusion

Pultrusion is a continuous manufacturing process for creating constant cross-sectional profiles like tubes. This method pulls carbon fiber strands through a resin bath and then into a shaping die. As the resin-impregnated fibers pass through the die, they're cured, resulting in a hardened tube of the desired shape and dimensions.

Advantages:

- Ensures uniform profiles with precise dimensions and properties along the tube length.

- Exceptional strength in a lightweight structure suitable for demanding applications.

- Continuous process offering high production rates, reducing time and labor costs.

- Capable of creating varied cross-sections, meeting industry needs with customized designs.

4. Resin Transfer Technique

This technique involves laying carbon fiber sheets onto a mold and coating them with release film. The fiber-coated film is then cut and laid onto a second piece of release film, with the fiber side facing up. The two pieces of film are then joined together using a roller or squeegee, ensuring a tight bond and even distribution of the fibers. The assembled package is then heated using a heat press or oven, allowing the resin to flow and coat the fibers. Once the resin is fully cured, the tube is carefully removed from the mold. This method is suitable for small to medium-sized tubes and offers a quick and easy way to create a carbon fiber tube.

Advantages:

- Precision in fiber orientation for optimized strength and flexibility.

- Simplicity aids efficiency in small to medium-sized tube production.

- Flexibility in design for tailored performance in thickness, layering, and composition.

- Faster method compared to some techniques, reducing production time.

Carbon fiber tubes continue to evolve, driven by advancements in materials science and manufacturing technologies. As these methods improve, we can anticipate even more durable, lightweight, and versatile tubes that push the boundaries of innovation across industries.

Source by- https://medium.com/@nitprocomposites/4-different-ways-of-making-carbon-fiber-tubes-ba79baaf96d8

Comments