-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Hydro-Cavitation Desulfurization

-

- Last updated January 18, 2024 0 comments, 78 views, 0 likes

More from qian liu

More in Politics

Related Blogs

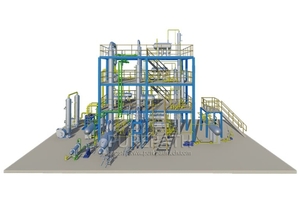

Revolutionizing Clean Fuel Production with Hydro-Cavitation Desulfurization

Body

Understanding Hydro-Cavitation Desulfurization

Hydro-cavitation desulfurization is a sophisticated process that utilizes the power of cavitation – the formation and collapse of bubbles in a liquid – to efficiently remove sulfur compounds from fuel. This method is particularly effective in eliminating sulfur, a major contributor to air pollution and acid rain when released during combustion.

The Ultrasonic Oxidative Desulfurization Plant

At the heart of this technological evolution is the Ultrasonic Oxidative Desulfurization Plant. This state-of-the-art facility integrates ultrasonic waves with oxidative processes to enhance the desulfurization efficiency of hydrocarbon-based fuels. The plant operates on the principle of creating controlled cavitation within the fuel, breaking down sulfur compounds, and facilitating their removal.

Key Advantages:

- Enhanced Desulfurization Efficiency: The Ultrasonic Oxidative Desulfurization Plant significantly improves the efficiency of sulfur removal compared to traditional methods. The ultrasonic waves create microbubbles that help break the sulfur bonds, making it easier to extract these undesirable compounds from the fuel.

- Reduced Environmental Impact: By minimizing sulfur content in fuels, Hydro-Cavitation Desulfurization contributes to a significant reduction in harmful emissions during combustion. This not only improves air quality but also aligns with global efforts to combat climate change and promote sustainable practices.

- Cost-Effective and Scalable: The implementation of the Ultrasonic Oxidative Desulfurization Plant offers a cost-effective solution for clean fuel production. The scalability of this technology makes it adaptable to various production capacities, providing flexibility for different industrial applications.

- Compliance with Environmental Regulations: As governments worldwide tighten regulations on sulfur content in fuels to curb pollution, the Ultrasonic Oxidative Desulfurization Plant positions itself as a crucial tool for industries seeking compliance with stringent environmental standards.

Conclusion:

In the ever-evolving landscape of clean energy production, Hydro-Cavitation Desulfurization, driven by the advancements in the Ultrasonic Oxidative Desulfurization Plant, stands out as a beacon of innovation. This transformative technology not only enhances the efficiency of fuel desulfurization but also aligns with the global commitment to sustainable and eco-friendly practices. As industries increasingly adopt such cutting-edge solutions, the Ultrasonic Oxidative Desulfurization Plant is poised to play a pivotal role in shaping the future of clean fuel production.

Comments