What is Drillers Method Used in Well Control

Body

Ensuring safe and efficient drilling operations while minimizing risks in the oil and gas industry hinges on effective well control techniques. Among these, the drillers method, also known as the "wait and weight" approach, stands out as a cornerstone practice for maintaining pressure equilibrium and averting uncontrolled wellbore flows. Let's delve into the intricacies of the drillers method, encompassing its principles, procedures, and the pivotal role of training in its execution.

Principles Underpinning the Drillers Method

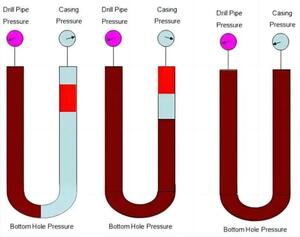

The drillers method operates on a set of fundamental principles aimed at promptly regaining control of a well following the detection of formation fluid influx.

Influx Detection: Early identification of influxes, whether oil, gas, or water, is paramount. Drilling parameters like fluid returns, pit gain, and mud logger data are meticulously monitored for any deviations indicative of an influx.

Well Closure: Upon confirming or suspecting an influx, immediate closure of the well is initiated. Blowout preventers (BOPs) are activated to seal the wellbore, curtailing further influx and safeguarding the rig crew.

Kill Weight Calculation: Calculating the requisite kill weight of drilling mud becomes imperative. This weight is tailored to counterbalance formation pressure and halt the influx, factoring in formation type, depth, and mud characteristics.

Mud Weight Adjustment: Dense additives such as barite or calcium carbonate are introduced to boost mud density, offsetting formation pressure. Precise adjustment is crucial to maintain effective control without exacerbating issues.

Controlled Pumping: Pumping of weighted mud ensues in a controlled manner, managing pump rates to forestall abrupt pressure spikes and ensure a safe, regulated process.

Continuous Pressure Monitoring: Real-time pressure monitoring via gauges and equipment is upheld throughout the procedure. This data aids in assessing kill weight performance and facilitating timely adjustments for sustained control.

Resuming Drilling: With the well stabilized and influx managed, drilling operations cautiously recommence, emphasizing the need to maintain mud weight at levels conducive to continued control.

Training and Preparation: Pillars of Success

The efficacy of the drillers method hinges on comprehensive training and thorough preparation. Here's why:

Safety: Rig crew safety is paramount. Adequate training empowers personnel to respond swiftly and effectively to well control challenges, mitigating the risk of accidents or blowouts.

Quick Decision-Making: Time sensitivity demands swift decision-making. Training equips drillers with the acumen to assess situations, calculate kill weights, and take decisive action under pressure.

Risk Mitigation: Thorough training minimizes errors, thereby mitigating the potentially catastrophic consequences of well control incidents.

Efficiency: Well-trained drillers execute operations with precision, minimizing downtime and equipment damage, translating into tangible cost savings.

Adaptability: Varied well conditions necessitate adaptability. Training ensures drillers grasp the method's concepts, enabling adept application across diverse scenarios.

Realistic Simulations: drilling and well control simulators provide invaluable hands-on experience, fostering confidence and competence in handling real-world contingencies.

Team Coordination: Effective communication and coordination are fostered through training, enhancing teamwork during critical moments.

Regulatory Compliance: Adherence to regulatory mandates underscores the importance of ongoing training to uphold industry standards and reputation.

Continuous Improvement: Regular training keeps drillers abreast of evolving practices and technologies, facilitating adept responses to emerging challenges.

Confidence and Competence: Proper training instills confidence and competence, vital attributes for navigating high-pressure situations with composure and proficiency.

In essence, training and preparation are indispensable components of well control, particularly when employing the drillers method. Investment in robust training programs ensures that drilling operations uphold safety standards, protect personnel and the environment, and maintain operational integrity.

Conclusion

In the realm of oil and gas exploration, mastery of well control techniques like the drillers method is imperative. Its systematic approach underscores the importance of proactive measures in upholding pressure equilibrium and averting wellbore influxes. By prioritizing training and preparedness, drilling enterprises can fortify their workforce against well control emergencies, safeguard lives, assets, and the environment, while upholding the integrity of drilling operations.

Comments