-

Encontrar enMiembros

Encontrar enMiembros Encontrar enVideos

Encontrar enVideos Encontrar enCanales

Encontrar enCanales

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy haga clic aquíPreferencia de privacidad

- Etiquetas - #laminating machine supplier

-

- Última actualización 11 de enero de 2021 0 comentarios, 310 vistas, 0 likes

- Ningbo, 浙江省中国 - Obtener las direcciones

More from rong hua

More in Politics

Related Blogs

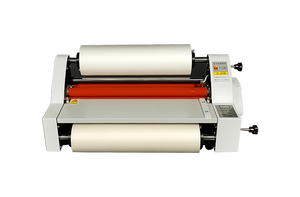

How To Use The Automatic Laminating Machine?

Cuerpo

Laminating film can not only improve the overall commercial image of advertisers, but also help to bring sales, but also save costs in the long run, because the finished product can be reused without being scratched or torn. In addition, valuable graphics can be protected, signs and posters can gain strength, and printing service providers can print signs at a low cost.

After the test film is confirmed, adjust the position of the positioner on the paper feeding table according to the width of the film to be coated, so that the film is in the middle of the film, and the article should not be tilted to avoid deviation . The items to be coated are sent to the feeding platform one by one and input to the feeding rubber roller, and the coated items will be automatically output from the rear discharge platform. Stop the machine only after all the coated items have passed the discharge rubber roller. Otherwise, there will be indentations on the coated items, which will affect the effect of the film. Tip: The space behind the laminating machine can make the output of the coated items smooth and avoid the deformation of the coated items due to blockage.

When the time interval between the completion of one operation and the next re-operation is long, when the machine stops and is on standby, please lower the set temperature by 5-10°C to facilitate the extension of the machine life. The machine has a memory function. The speed and temperature values used in the last operation before shutting down are automatically saved. When the machine is turned on the next time, the machine will automatically set the temperature and speed saved before shutting down. General strategy for setting speed and temperature during lamination: The combination of appropriate temperature, film tension and pressure holding time can provide outstanding and continuous lamination effects. Generally speaking, the holding time for thick objects or films is longer and the running speed is slower. For thin objects or membranes, the holding time should be shorter and run faster.

Ningbo Ronghua Digital is a laminating machine supplier. Such as automatic laminating machine, cardboard laminating machine, industrial laminating machine, wood laminating machine, etc. The VS500 laminating machine adopts hot rolled steel rolls and has a stable temperature control system, allowing users to control the temperature freely.

If you are interested in our products, you can click here: automatic laminating machine.

Fotos

Mapa

-

Ubicaciones en MyWorldGo

Información sobre la ubicación

- Ubicación: Ningbo, 浙江省中国 - Obtener las direcciones

- Dirección formateada: 中国浙江省宁波市

- Dirección: 宁波市

- Estado: 浙江省

- País: 中国

Comentarios