The Advantages of CNC Manufacturing Shops in Streamlining Industrial Production

Corps

In today's fast-paced industrial landscape, CNC manufacturing shops have become an integral part of streamlining production processes. With the advent of Computer Numerical Control (CNC) technology, manufacturers can now achieve higher levels of precision, efficiency, and productivity. This article explores the various advantages that CNC manufacturing shops offer in streamlining industrial production.

Enhanced Precision

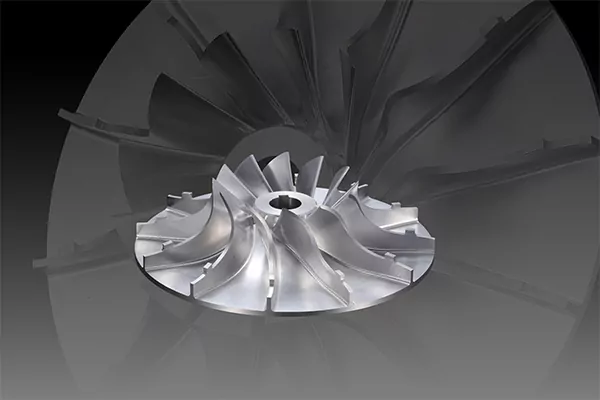

One of the key advantages of CNC manufacturing shops is the enhanced precision they provide. CNC machines are programmed to execute tasks with incredible accuracy, ensuring consistent results every time. The use of computer-controlled systems eliminates the potential for human error, resulting in products that meet the most stringent quality standards. Whether it's cutting, drilling, or shaping, CNC machines can achieve intricate details and tight tolerances that would be difficult to replicate manually.

For example, in the aerospace industry, where precision is of utmost importance, CNC manufacturing shops play a crucial role in producing components that meet the stringent requirements for safety and performance. The ability to consistently manufacture parts with precise dimensions and complex geometries ensures the reliability and functionality of aircraft systems.

Increased Efficiency

CNC manufacturing shops also offer increased efficiency in industrial production. Unlike traditional manual machining methods, CNC machines can operate continuously, 24/7, with minimal downtime. Once the initial setup is complete, CNC machines can run autonomously, reducing the need for constant human supervision. This allows manufacturers to optimize their production schedules and maximize output.

Moreover, CNC machines can perform multiple operations in a single setup, eliminating the need for manual tool changes and reducing production time. For instance, a CNC lathe can perform turning, drilling, and milling operations in one continuous process, significantly improving efficiency and reducing production costs.

Improved Productivity

The use of CNC manufacturing shops greatly enhances productivity in industrial production. CNC machines can produce parts at a much faster rate compared to traditional machining methods. The automation and precision of CNC technology allow for faster cutting speeds and higher feed rates, resulting in shorter cycle times.

Furthermore, CNC machines can be programmed to replicate the same operation repeatedly, ensuring consistent and rapid production of identical parts. This is particularly advantageous in industries such as automotive manufacturing, where large quantities of components need to be produced within tight deadlines.

Flexibility and Adaptability

CNC manufacturing shops offer a high level of flexibility and adaptability in industrial production. CNC machines can be easily reprogrammed to produce different parts, allowing manufacturers to quickly adapt to changing market demands. This flexibility enables businesses to stay competitive and responsive to customer needs.

Additionally, CNC machines can work with a wide range of materials, including metals, plastics, and composites. They can handle complex shapes and geometries, making them suitable for a variety of applications across different industries. Whether it's prototyping, small-scale production, or mass production, CNC manufacturing shops can cater to diverse manufacturing requirements.

In conclusion, cnc manufacturing shops provide numerous advantages in streamlining industrial production. From enhanced precision and increased efficiency to improved productivity and flexibility, CNC machines have revolutionized the manufacturing landscape. By leveraging the capabilities of CNC technology, manufacturers can achieve higher quality products, reduce production time, and stay competitive in today's global market.

commentaires