Lyophilization Equipment Manufacturers Share Freeze-Dried Protective Agents

Body

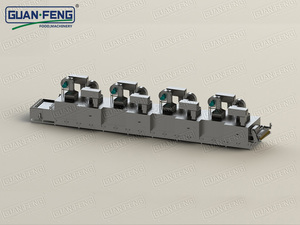

During the freeze-drying and storage of foods, pharmaceuticals, and organisms, many factors affect the stability of the active components and may even lead to inactivation. A large number of experimental studies have shown that in addition to some foods, human plasma, milk, and other materials can be directly freeze-dried, most pharmaceuticals and biological products need to add appropriate freeze-drying protective agents and additives to prepare a mixture. Perform effective freeze-drying and storage. The following Guanfeng Lyophilization equipment manufacturers share the classification of freeze-dried protective agents:

- Classification by relative molecular weight

- Low molecular compound. It can also be divided into acidic substances, neutral substances, and alkaline substances.

- Polymer compounds. Mainly such as albumin, gelatin, soluble starch, dextrin, gravy, pectin, acacia, algae, etc., as well as natural mixtures such as skimmed milk, serum and the like.

Regarding the mechanism of action of the protective agent, it is generally believed that the low molecular compound directly functions in the lyophilization process, and the polymer compound promotes the protection of the low molecular compound. Therefore, when preparing a protective agent formulation, generally, a low-polymer compound is used in combination.

Second, according to the function and nature of the protective agent

1. Freeze-drying protection. A substance that prevents denaturation of the active component during freezing and drying.

- Filler. A substance that prevents the effective component from sublimating along with water vapor and shaping the active component.

- Anti-leveling agent. It is used as a substance to prevent oxidative deterioration of biological products during the freeze-drying process and during storage. Such as vitamin D. Vitamin E, protein hydrolysate, sodium thiosulfate and the like.

- Acid-base conditioner. A substance capable of adjusting the pH of a biological product to the most stable region of the active material during the freeze-drying process and storage.

Third, according to the type of substance

Such as sugars/polyols, polymers, surfactants, nitrogen acids, and salts.

In the freeze-dried formulation, a variety of additives are used in addition to the active component and solvent. Some of these additives are called protective agents, some are called additives, and some are called excipients, but so far there is no uniform name. The term excipient comes from the pharmacy, which means An inactive material excipient which constitutes a drug into an antigen, in particular, a substance which is added in order to prepare a pill or a tablet in the case where there is a large amount of liquid in the drug mixture. Later, the name of the excipient was expanded. According to literature statistics, the term "excipient" is used more in freeze-dried formulations.

In the freeze-drying formula of biological products, some additives can only play a specific role, while other additives can play several roles at the same time.

Comments