More from krista medicalmould

More in Politics

Related Blogs

Archives

Social Share

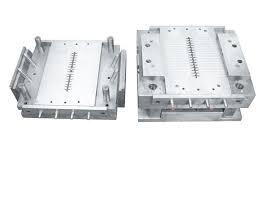

What are the precautions for plastic injection mold cavity processing? What are the main items of core processing?

Body

What are the precautions for plastic injection mould cavity processing? What are the main items of core processing?

The precautions for cavity processing are as follows.

① In the CNC milling of cavity parts, from the regular shape blank to the part processing before smoothing (mainly refers to polishing), since the cavity is usually manufactured with matching copper electrodes, the milling process is generally rough The machining toolpath is mainly used, supplemented by local surface finishing.

② With parting surface and pillow surface, when they are to be processed together, the parting surface and pillow surface should be processed in place, leaving no margin. Leave a margin of 0.2~0.5mm in the cavity for sparking. Can leave a margin of 0.5mm. There can be a margin of 0.1mm for the cavity bumping position and rubbing position, which is used for moving and fixing molds.

③ Use a large-diameter fillet knife (knife handle) for rough machining. If the diameter of the tool is too small, it is easy to break and snap off the knife. The fillet cutter has a large diameter, good rigidity, and durability. It is usually used for roughing of the cavity when roughing, and it is also used for finishing as much as possible.

When the rigidity of the tool is not enough, it will bend and vibrate, which will result in the failure of normal processing, which is called a bullet knife.

④ In the case of using the system default parameters, the tool path range in surface machining is calculated based on the movement path of the tool center axis, that is, the actual machining area is one side larger than the selected tool path range limit box (boundary limit box) by one tool radius value. Set the parameters of the tool path range limit box reasonably to avoid the processing range exceeding the actual processing needs.

The precautions for core processing are as follows.

The core is made of steel like the cavity, and the material is harder, so you should try to use a tool with a handle for processing. The problem often encountered in core processing is that the ball-end knife is not easy to remove sharp corners. At this time, the end mill can be used to go to the curved surface and the inclined surface to clean the corner.

Pay attention to the cooperation of the core and the hidden core frame. When processing the hidden core frame, pay attention to the empty knife several times, otherwise the hidden core frame will have a slope, that is, the upper side is accurate and the lower side is small, so it is difficult to match Die, especially the deeper hidden core frame, must pay attention to this problem, the cutting tool of the finishing frame should also be new, and a larger tool should be used.

In order to facilitate mold matching, the frame size can be 0.02mm smaller than the shape of the core, and the tolerance and step distance during core finishing can be slightly larger, with a tolerance of 0.01~0.03mm and a step distance of 0.2~0.05mm.

For more product information, please click here: Laboratory Plastic Ware Mould.

Comments