-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Bucket Mould

-

- Last updated March 17, 2021 0 comments, 288 views, 0 likes

More from rixiang alex

More in Politics

Related Blogs

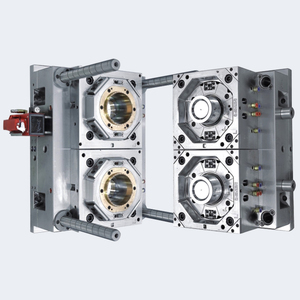

Injection Plastic Pail Mould Process Production

Body

Nowadays, the application of plastic products has been quite extensive, and the production process of plastic products has not yet been improved. As we all know, the main production method of plastic products is injection molding.

1. Injection Plastic Pail Mould process product molding cycle, including injection time and product cooling time. Effective control of these times has a profound impact on the quality of the product. Before plastic injection molding, we should clarify the product molding Plastic furniture mould cycle through sample patterns and other methods.

2. The temperature of the injection mold, different plastic particles, different crystallization temperature and speed, product appearance, deformation, size, plastic mold, etc. have different requirements, which makes the temperature change of the injection mold when using different plastics, product requirements, etc. When, the control method is different.

3. Molten plastic injection pressure. The plastic faces great resistance during the process of filling the mold cavity. This makes the injection pressure directly determine the size, weight, density, appearance, etc.! If any of these factors are affected, then the product will become waste. This requires injection molding engineers to reasonably define injection pressure control based on product combination factors.

4. The injection molding speed is fast, and the injection speed has an important influence on the final appearance quality of the product. The injection speed is usually achieved by adjusting the amount of oil supplied to the injection cylinder per unit time.

5. The temperature of the barrel and the temperature of the melt. The temperature of the melt can be measured at the nozzle or by the air jet method. The melt temperature plays a major role in the flow properties of the melt. Injection molding plastics have no specific melting point. It is the temperature range of the molten state. The control of the two temperatures also plays a vital role in the quality of the product.

We are a professional molding company, sell different design of mold, 18L Bucket Mould is one of them,welcome to visit our website.

Comments