A Critical Determination For The Success Of Bucket Injection Molding

Body

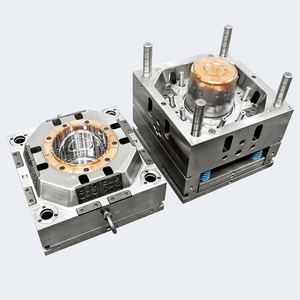

By its very nature, plastic injection molding is a manufacturing process that creates a lot of pressure. The two halves of the mold are brought together by the injection molding machine, and the molten plastic resin is injected into the Bucket Mould at high pressure. There is pressure to push the mold halves apart, so the machine must be capable of applying enough opposing pressure to hold them closed during the filling/packing/cooling phase of the process.

Clamping force refers to the force applied to a mold by the clamping unit of the injection molding machine. There are many factors and formulas that go into measuring the force required hold the mold closed. This page covers a high-level explanation of the factors that are considered in determining the clamping force that will be required to injection mold a certain part. This is a critical determination for the success of the parts – too little clamping force can cause problems, and too much clamping force can cause problems for the parts, mold or machine.

Normally, the injection molding machine clamping force rating is stated in tonnage. A 200-ton machine, for example, is capable of producing a maximum clamping force equivalent to a total of 200 tons. The clamp tonnage requirement is used to select a capable machine that will prevent part defects, such as excessive flash.

The required clamping force can be calculated from the cavity pressure inside the mold and the shot projected area, on which this pressure is acting. There are variables that affect the clamping force calculation, such as the surface area of the part, the material type (low-flow versus high-flow plastic), and the depth of the part.

Surface Area

The first step in determining appropriate clamp tonnage is to calculate the surface area of the part. This simply means getting the square inch area of the cavity by multiplying the length by the width. If it is a multi-cavity mold, multiply the number by the number of cavities. Then any cored-out surface area is subtracted from the area, and the area of a cold runner has to be taken into consideration if the mold has one.

Once the surface area is calculated, the area is then multiplied by a tonnage factor. Typical tonnage factors can range from 2 to 8 tons per square inch, depending on the material. For example, if we have a 6” X 6” part, the surface area is 36 square inches. Let’s further assume that our material calls for a 5X mold clamp factor. 36 times 5 equals 180, so based on our calculations up to this point, we will need to run these parts on an injection molding machine capable of at least 180 tons of clamping force.

A 10% safety factor should be added, so a final injection mold clamp force of 198 tons is needed. So at this point in our calculations, a 200-ton machine would be a good choice. Keep in mind that we need to select the right clamp tonnage machine – too much can cause problems for the parts or machine.

Once we have this starting point for calculating the proper clamp tonnage, other factors have to be considered. They include the melt flow rate/index, flow length, number of gates and their size and location, and part dimension. Since the purpose here is to present a high-level overview of clamp tonnage, we will only discuss melt flow and part dimension.

Melt Flow

After calculating the surface area, the next item that needs to be considered is how the material flows. Plastic resins are rated according to their viscosity, and their flow rating is expressed as a Melt Flow Rating (MFR), or Melt Flow Index (MFI), which may be found on the material data sheet.

There is an inverse relationship between viscosity and the MFR. Materials with a low viscosity have a high melt flow, and therefore require less clamping force. Conversely, materials with a high viscosity have a low melt flow, and require more clamping force.

Part Depth Dimension

The last clamp tonnage factor we’ll discuss here is the depth of the part. If the depth of the part is greater than 1 inch, we have to factor this into our calculation. This does not refer to the thickness of the wall, but to the total depth of the part. For every inch of depth over one inch, we need to increase the clamping force calculation by 10%. So, for a part with a total depth of 2 inches, we need to add 10% to our calculation.

Potential Harm From Excess Tonnage

Now that we’ve gone through all our calculations and added a 10% safety factor, we are ready to choose the right machine, with the appropriate clamp tonnage, to run our parts. As previously mentioned, there is a danger in choosing an injection molding machine with too much clamp tonnage. Doing so can cause part defects, mold damage or machine damage.

Some typical molding defects that are immediately apparent on parts are burns, gloss level changes and short shots caused by excessive clamping force.

Besides the immediate defects on the parts, too much clamp tonnage can also have negative long-term side effects on the mold. It can cause rolled parting lines, crushed vents, and even break inserts or crack the core or the cavity block.

As for the possible effects on the injection molding machine itself, too much clamp force can crack hydraulic cylinder mounting plates. It can also cause deformed platens or even fracture the machine frame.

In addition to all the negative effects too much clamp tonnage can create such as part defects or damage to the mold or machine, it can also have a financial impact. A higher tonnage machine generally costs more to run than a lower tonnage machine, so selecting a machine with too much clamping force for the part can cause the total cost of the job to be unnecessarily higher. Downtime and the costs of repairing damage can also add unnecessary cost to the project.

Injection Molding Pressure & Clamp Tonnage Summary

In summary, it is very important to calculate the required clamp tonnage for a given injection molding job, select an injection molding machine that provides that clamping force, and avoid selecting one that has excessive clamping force for the job.

We are a professional molding company, sell different design of mold, Pail Mould is one of them,welcome to visit our website.

Comments