-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

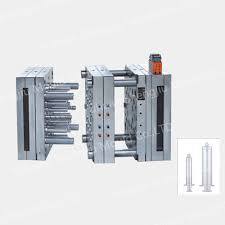

- Tags - #Syringe Mould

-

- Last updated April 14, 2021 0 comments, 247 views, 0 likes

- 中国台州市玉环市 Yuhuan Dao - Get Directions

More from krista medicalmould

More in Politics

Related Blogs

Syringe mould related test

Body

Test method for body tightness of syringe mould:

(1) Positive pressure method: Inhale the syringe with nominal volume of water, use the axial pressure and lateral pressure specified in Table 1 to act on the core rod for 30s, and there should be no leakage at the contact part of the outer jacket and the piston.

(2) Negative pressure method: maintain 60s±5s under the action of 88kPa negative pressure, the contact part of the jacket and the piston must not leak, and the piston and the core rod must not be separated.

Simple test method of MED-01 equipment:

The MED-01 medical packaging performance tester produced by Labthink meets the requirements of GB 15811-2001 and GB 15810-2001 standards. It can be professionally used for disposable sterile syringes and disposable sterile injection needle products. High-precision testing of performance, puncture force of the needle tip of the injection needle, the tightness of the syringe body, the connection firmness of the injection needle needle seat and the needle tube, and the matching force of the injection needle needle seat and the sheath.

(1) Prepare the sample according to the relevant standards, inject ordinary water into the syringe to remove residual air, insert the needle cap to block the needle, adjust the clamp to clamp the sample;

(2) In the test type box, select "body tightness" and set the corresponding test parameters and sample parameters;

(3) Click to start the test and observe the sample. No leakage should be observed behind the needle seat or piston; after the single test is over, the upper chuck will return to its position, and the result will be automatically calculated and returned to the test interface to start the next sample. Test. So after the sample test is finished, click "Generate Results".

Simple operation method of MFY-01 equipment

MFY-01 sealing tester adopts the testing principle of negative pressure method, which can be professionally used for testing the negative pressure sealing performance of syringe body. The operation is simple and convenient.

(1) Immerse the test sample in the water in the vacuum chamber.

(2) Put on the sealing cover and set the vacuum pressure parameters and holding time to be reached.

(3) Turn on the vacuum pump, start vacuuming, and press the start button on the equipment to start the test.

(4) Observe whether the syringe body leaks during the vacuuming process or the pressure maintaining process, and whether the piston is detached.

For details, please contact: syringe mould wholesaler.

Photos

Map

-

Locations on MyWorldGo

Location Information

- Location: 中国台州市玉环市 Yuhuan Dao - Get Directions

- Formatted Address: Yuhuan Dao, 玉环市台州市中国

- Street Address: Yuhuan Dao,台州市

- Country: 中国

Comments