CENTRIFUGAL PUMPS: VITAL FOR MULTIPLE APPLICATIONS

Body

What Are Single Stage Pumps?

Centrifugal pumps are the most common type of pump available, accounting for roughly 70% of all pump types. They belong to one of three pump families.

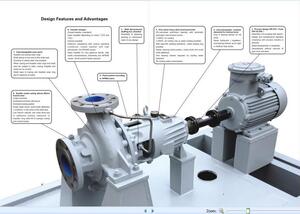

When powered by a motor, a single-stage centrifugal pump consists of one impeller spinning on a shaft inside a pump casing built to create fluid flow. It is one of the most basic pump designs available, with numerous variations to meet the duty requirements of various applications. The impeller design is modified to handle clean, dirty, and solid-laden liquids and a variety of mechanical seal styles to accommodate different applications.

When determining if a single-stage should be listed, there are four critical criteria to consider:

- Performance

-

Rated capacity

- Pump life

- Simplicity of Operation

- Cost

Performance

Single-stage pumps are made to move large amounts of water quickly. A single-stage pump is probably the best option if you have an apparatus that regularly flows at or near the pump's rated power. It will cruise at a higher rate than the rated power (with less engine speed).

Rated Capacity

Single-stage pumps perform better when they are operated at or near their rated capacity, but most fire departments' pumpers aren't often used at or near their rated capacity. Pumps are sometimes used at only a fraction of their rated power. Take a look at the equipment in your fleet. When was the last time a pump at a fire station operated at total capacity? Most fires are extinguished with one handline flowing around 100 GPM for many departments (including the major ones).

Pump Life

You'll need to spin a single-stage pump faster than a two-stage pump if you're pumping less than rated power. The engine can use more fuel as a result of this. When run at governed rpm, a typical diesel engine consumes about 20 gallons of fuel per hour. This may not seem to be a significant sum, but over the life of the apparatus – and at today's fuel rates – the dollars will quickly add up.

Additionally, running the engine faster than required causes the engine, frame, transmission, and driveline components to wear out more quickly. Most agencies don't have to worry about this because today's fire engines, information, and drivelines are almost the same as those used in over-the-road vehicles, which can travel hundreds of thousands of miles before having to be overhauled. However, there is no denying that using a two-stage pump will reduce the amount of wear and tear on these components.

Finally, single-stage pumps are not designed to create high pressures, even though they are designed to flow vast quantities of water. In reality, a single-stage pump would need to spin faster to develop 125 GPM at 200 psi (a standard 300-foot 1-1/2-inch attack line) than it would to pump 1,500 GPM at 150 psi. This is because the impeller needs to flow more than 1,500 GPM at this pace. However, the nozzle at the hose's end restricts the flow through the impeller to 125 GPM. As a result, the water leaving the impeller has nowhere to go, causing intense turbulence within the pump. Recirculation cavitation is the outcome of this phenomenon, and it can quickly kill a centrifugal device.

Simplicity of Operation

A single-stage pump is unquestionably easier to operate since the operator of the latter must choose whether to use the pump in volume or pressure mode. A single-stage pump eliminates the need for such a decision.

When running a single-stage pump, the operator needs to increase the engine speed to achieve the desired flow or pressure. However, the operator's only option is to do so.

Cost

Single-stage pumps are less expensive, but the difference is negligible compared to the total expense of the apparatus over its useful life. And, as previously said, the higher initial cost would be offset by fuel savings over the equipment's lifetime.

Comments