-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

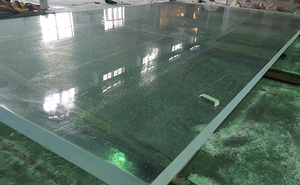

- Tags - #Large Acrylic sheet

-

- Last updated July 23, 2019 0 comments, 333 views, 0 likes

- Jiashan - Get Directions

More from mi le

More in Politics

Related Blogs

Acrylic has obvious advantages over other materials

Body

Acrylic is a semi-crystalline thermoplastic. It has high impact resistance, strong mechanical properties, and resistance to various organic solvents and acid and alkali corrosion. It is widely used in industry.

1. The appearance gloss is high. Bright color, lasting more than ten years. This is incomparable to metal or inkjet. Special color saturation and durability as well as excellent external luster are clear and transparent in sunlight. The sparkling feeling is the customer's perception. One of the important reasons for choosing acrylic acid.

2. The material itself has strong light: the acrylic plate used in outdoor advertising industry has excellent light transmittance, built-in light source, and even and soft brightness at night. Compared with neon lights, acrylic is the whole lamp, unlike neon lights, the lines are shiny. Softer than neon lights.

3. Built-in light source: no external wiring is required and it is not easy to damage. First, there is no external wiring, which solves the problem of unattractive wiring of external neon lights. The utility model solves the problem that wires and light sources are easy to short circuit and burn when exposed to air. And Due to the good seal of acrylic acid, it solves the problem that the lamp cannot be turned on in rainy days. Use rain and snow as usual.

4. Stable physical properties and strong resistance to deformation at high and low temperatures. This is one of the important characteristics of acrylic acid used in outdoor advertising. First of all, it has strong anti-ultraviolet ability, which is also one of the reasons why it does not fade. In addition, it can withstand high temperatures of 70 c. Low temperature-50 c. There will be no change during this interval. There is no such temperature difference in most parts of China. Therefore, enterprises can use it safely outdoors.

5. Machining is very powerful (1) thermoforming performance: it is just described between 70°C and 50°C, the temperature can reach a certain height, and acrylic plates soften rapidly. After softening, the mold can be molded into various shapes according to the shape of the mold, and after cooling to normal temperature, the physical properties are stable. (2) strong machinability: acrylic plate can be formed by cutting, sawing, drilling and other tools. Flexibility is relatively good. In general, acrylic sheets do not crack (compared to plexiglass).

If you want to know more, you can click here: Large Acrylic sheet.

Comments